A pharmaceutical printer that can check it's own printing

Client: InterVision Global

Industry: Industrial Machine Vision / Pharmaceutical

“Raymont-Osman were thoroughly professional in their approach, delivery and support from the concept through to the manufacturing and assembly drawings. I have no hesitation in recommending Tom and his team. The quality, detail and support was great!”

Mark Worlidge

Managing Director

InterVision Global

InterVision Global are a leader in machine vision systems, supplying companies within the Food & Beverage, Healthcare & Pharmaceutical, Medical Device & Life Sciences, Defence and Machine Building market sectors.

Their systems and solutions allow manufacturers to adhere to ever-increasing levels of industry compliance, improve productivity & yield levels and deliver a competitive advantage in their manufacturing processes.

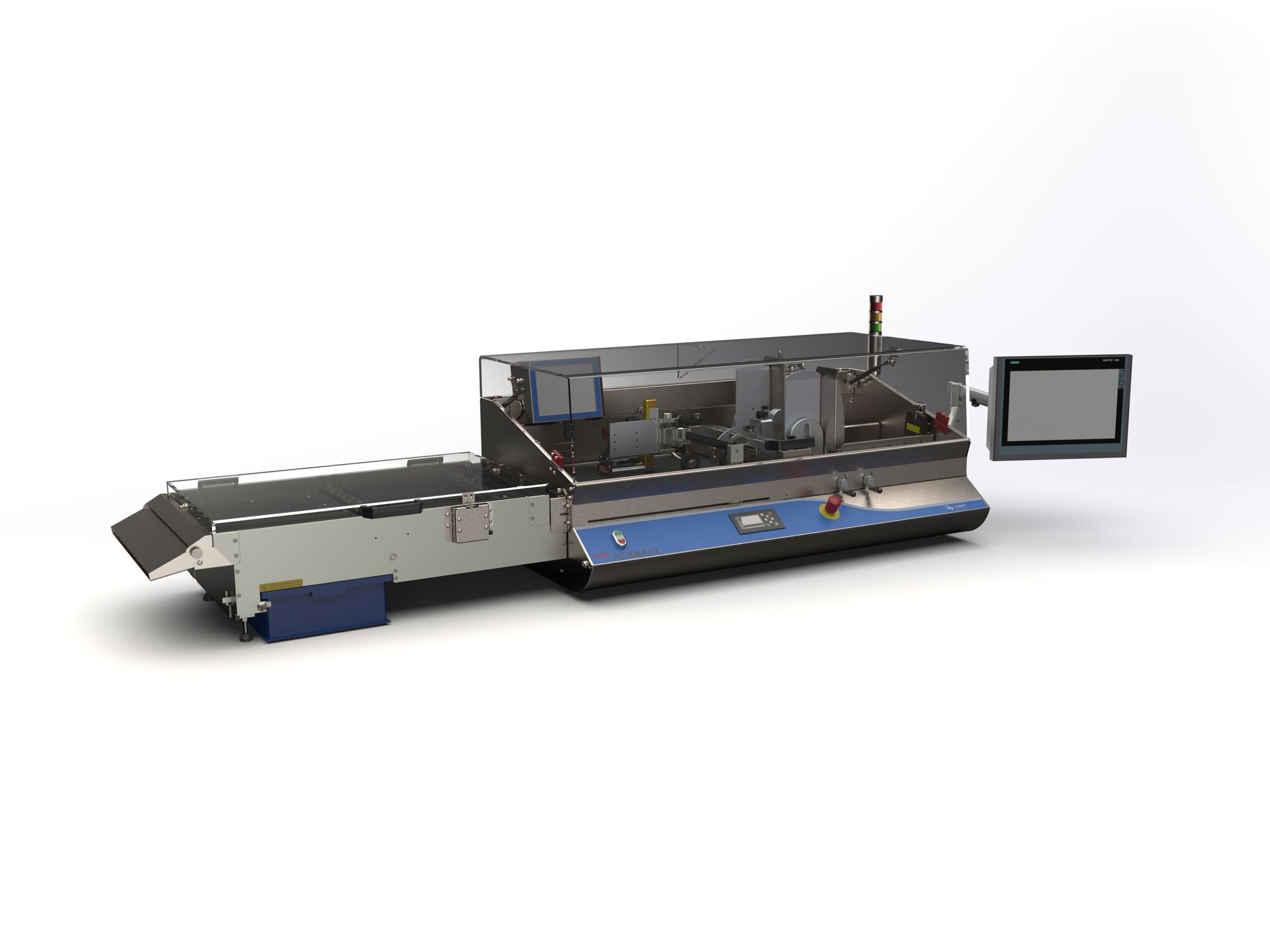

The UDA Formaxx is a printer for pharmaceutical and healthcare packaging with an incorporated vision system to check the quality of the print and a reject station to remove any parts not meeting the required quality level. Our Mechanical and Manufacturing Engineers designed a casing for the machine that prevents access to moving parts in line with the machinery directive but still opens for loading and servicing. We also designed the clear acrylic lid that raises and lowers with assistance from two gas struts.

Services: Mechanical Engineering, Product Design, Finite Element Simulation, Motion Analysis, Design For Manufacture, Machinery Directives, Sheet Metal Design, Gas Strut Design

We have also Designed, Developed and Engineered the CanCode for InterVision Global