Whether you have a fully-formed product design in mind, or just a basic idea of what you want to create, we're here to help. As experts in all areas of product design, our talented team of designers and engineers can guide you every step of the way. From ideation to prototyping to production, we're dedicated to bringing your vision to life. So why wait? Get in touch today and let us help you create the perfect product.

Services

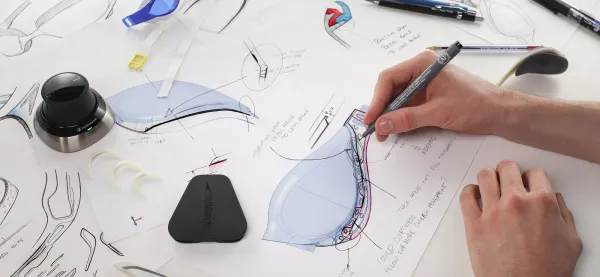

Industrial Design and Concept Design

Industrial Design is the creative search for the soul of a product, it makes a product usable, useful and aesthetically pleasing. It's our passion to create iconic products that stand out from the crowd.

See MoreMechanical Engineering and CAD Design

Our team of mechanical engineers and designers take pride in developing and implementing cost effective, intuitive, robust solutions for mechanical challenges. From structural concepts to detailed FEA.

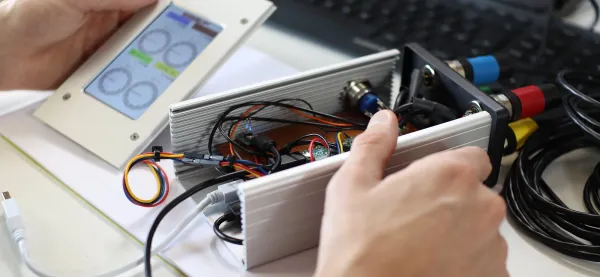

See MoreElectronics Engineering

The products around us are becoming increasingly digital and connected. From simple toys and game design to complex medical devices. We work with our clients to develop the brains behind their products and services.

See MoreSimulation and Testing

Virtual simulation and analysis with computer software allows us to investigate multiple design iterations and is an essential part of the product development process.

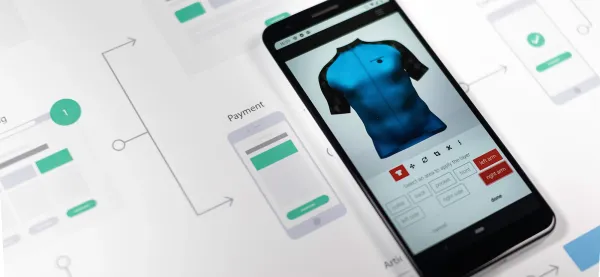

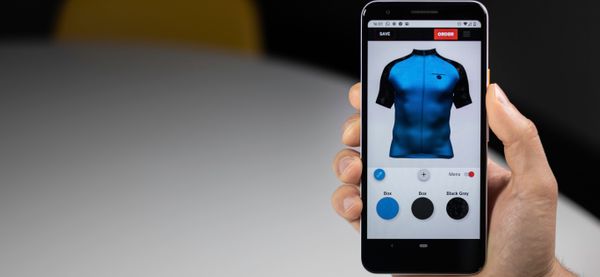

See MoreUser Experience & User Interface Design

We love to design products that are human centric and user focused. From the precise click of a button pad, to the smooth flow of a touchscreen interface. Both digital and physical experiences.

See MoreDesigning for Manufacture (DFM)

Through our wide range of services, we combine design, engineering and manufacturing considerations to create great products that are as functional as they are beautiful.

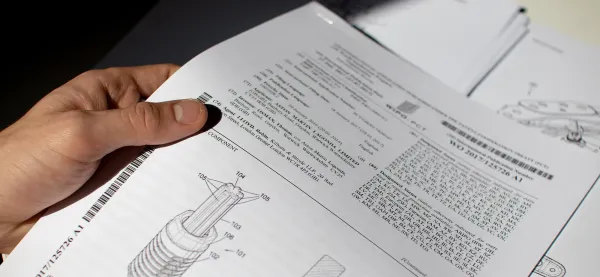

See MoreIntellectual Property, Patents & Legal

We help you to protect your ideas by offering specialist advice, support and service to ensure that you retain your intellectual property rights. We have extensive experience in a wide range of fields.

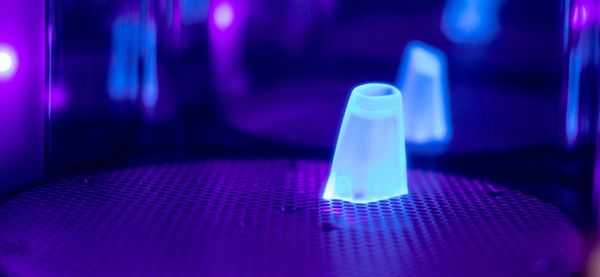

See MoreRapid Prototyping, 3D Printing and Model Making

Rapid prototyping, 3D printing and model making

See MorePhotorealism, Rendering, CGI and Animations

Photorealism, rendering, CGI and animations. Ensuring the product’s aesthetic suits your needs is a crucial aspect of effective product design. Using photorealistic rendering, our Design Team at Raymont-Osman will create visuals to communicate and sell your product or ideas.

See MoreProduction Support

At Raymont-Osman Product Design, we offer comprehensive support to our clients to ensure a successful product launch.

See MoreProduct Marketing Support

The launch, marketing and go-to-market strategy is critical in the success of your product. At Raymont Osman Product Design, we have an in-house marketing team to help you position your product in your market perfectly and drive sales.

See More