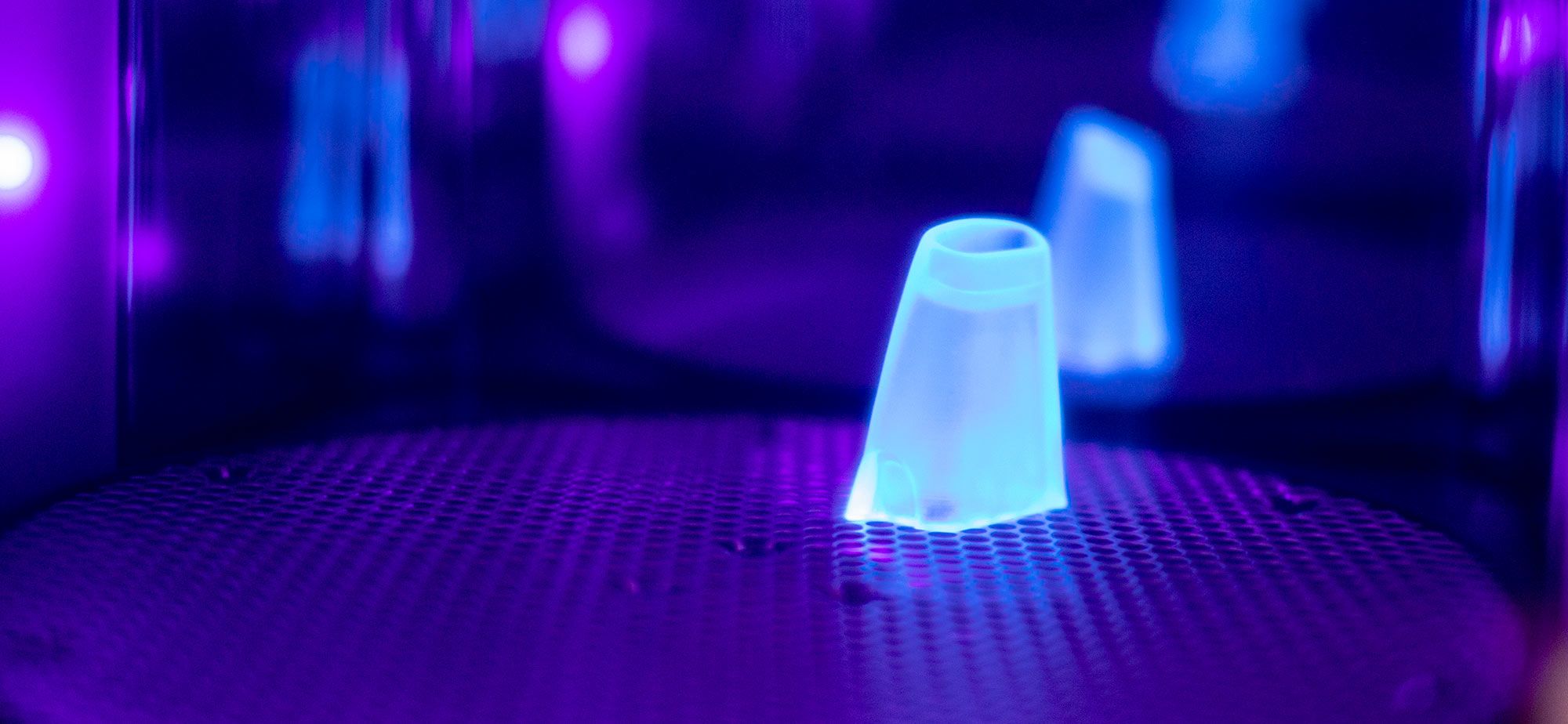

Our in-house printers enable us to create solid prototypes directly from CAD files, saving time and money compared to traditional manufacturing methods.

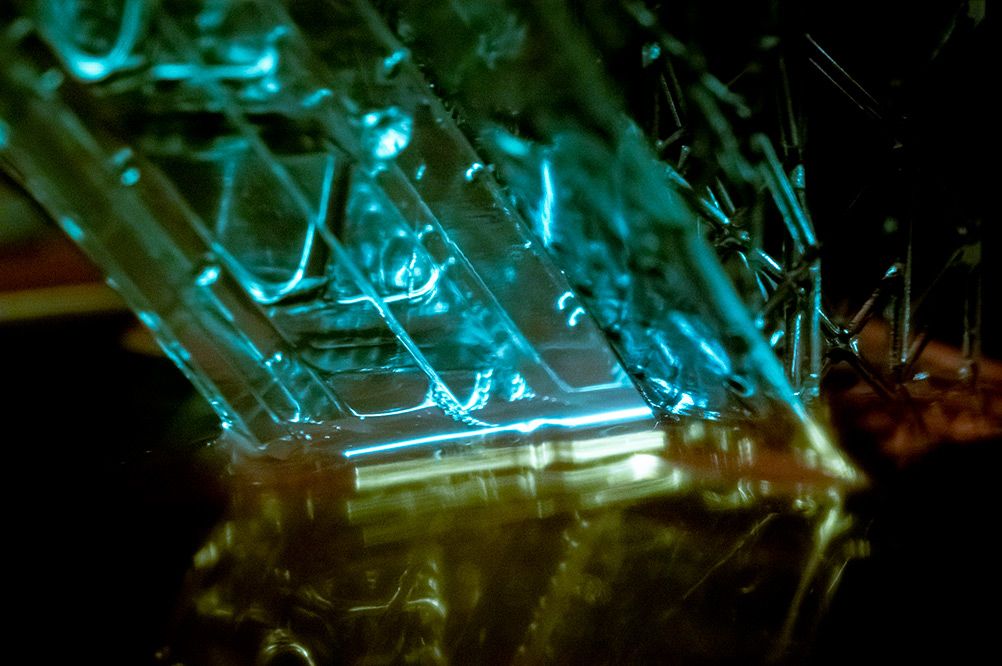

We use the Form 2 for specialist materials like flexible and ceramic parts, while the Form 3L is our workhorse for most structural and aesthetic parts in a more conventional resin. Our team of experts has developed specialist techniques for the Queen’s Baton, where we could print in wax and then use lost wax casting to make aluminium parts.

In addition to our in-house printers, we have access to a wider network of printers, including Selective Laser Sintering (SLS) for nylon parts that are strong and accurate enough to use in low-volume production.

One of the biggest benefits of 3D printing is the speed at which parts can be created. Our experienced product design team can design a part one day, set it printing overnight, and have a physical prototype to test and iterate the following day. This can dramatically reduce your time to market and give you a competitive edge in your industry.

Whether you need a quick prototype or a low-volume production run, our team can help you achieve your goals with the latest 3D printing technology. Contact us today to discuss your product design needs.