This will further enhance our capacity to produce large-scale, life-sized 3D print prototypes - in-house and quickly.

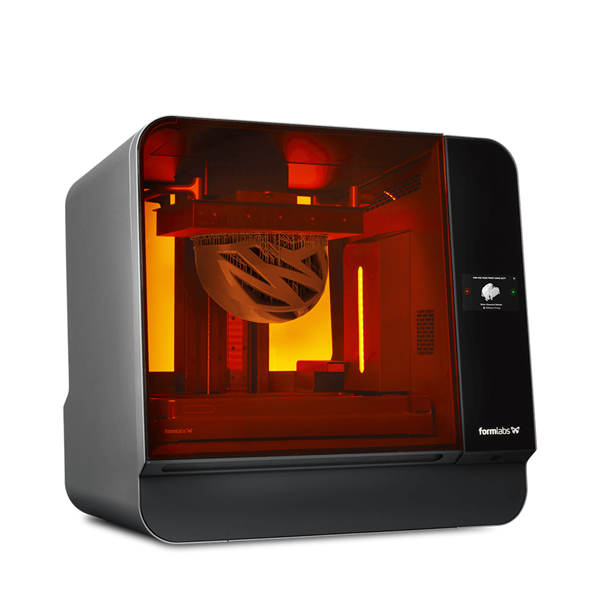

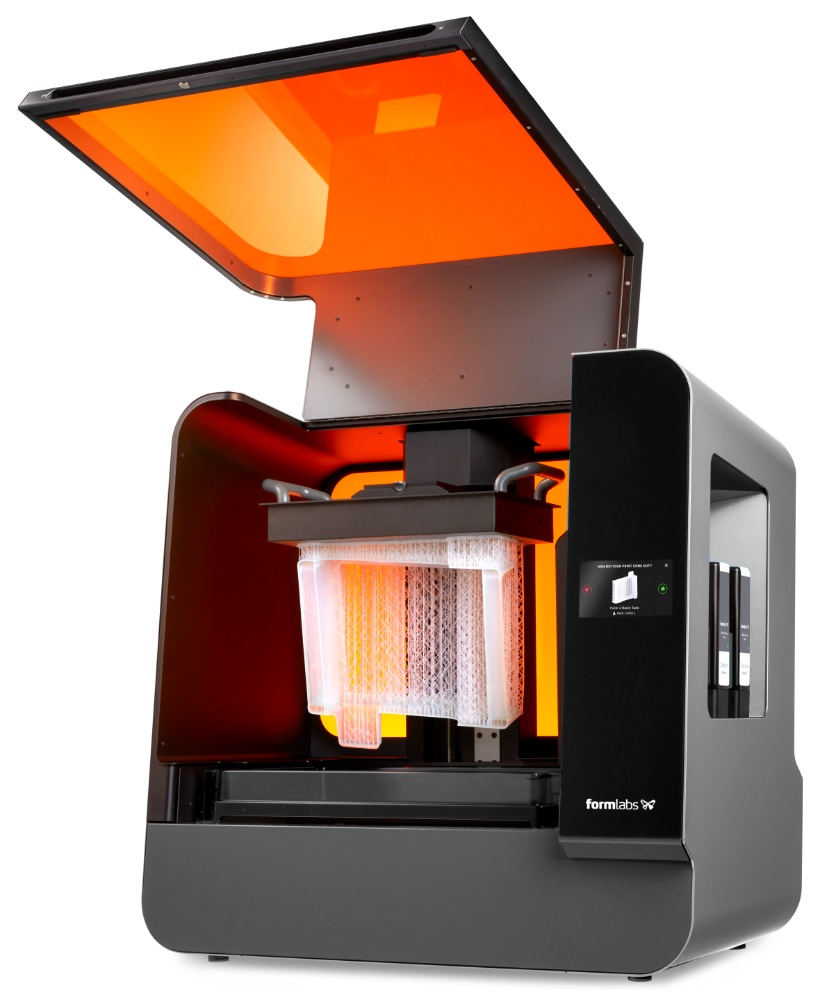

The enormous Form 3L has a build volume of 335 x 200 x 300 mm and can build single large pieces or dozens of smaller pieces simultaneously. It has twin resin cartridges and can hot swap empty ones while still printing and it also has the same easy programming and control software as the Form 2 3D printer that has been a key part of the Raymont-Osman set-up for years.

We are also now able to print round the clock, using Draft Resin which allows us to balance detail and speed to save time on bulky prototypes and enable super quick iteration.

We are currently working on a top-secret, extremely time-sensitive project (more to be revealed soon!!!) and the printer has been working away day and night for the past two days.