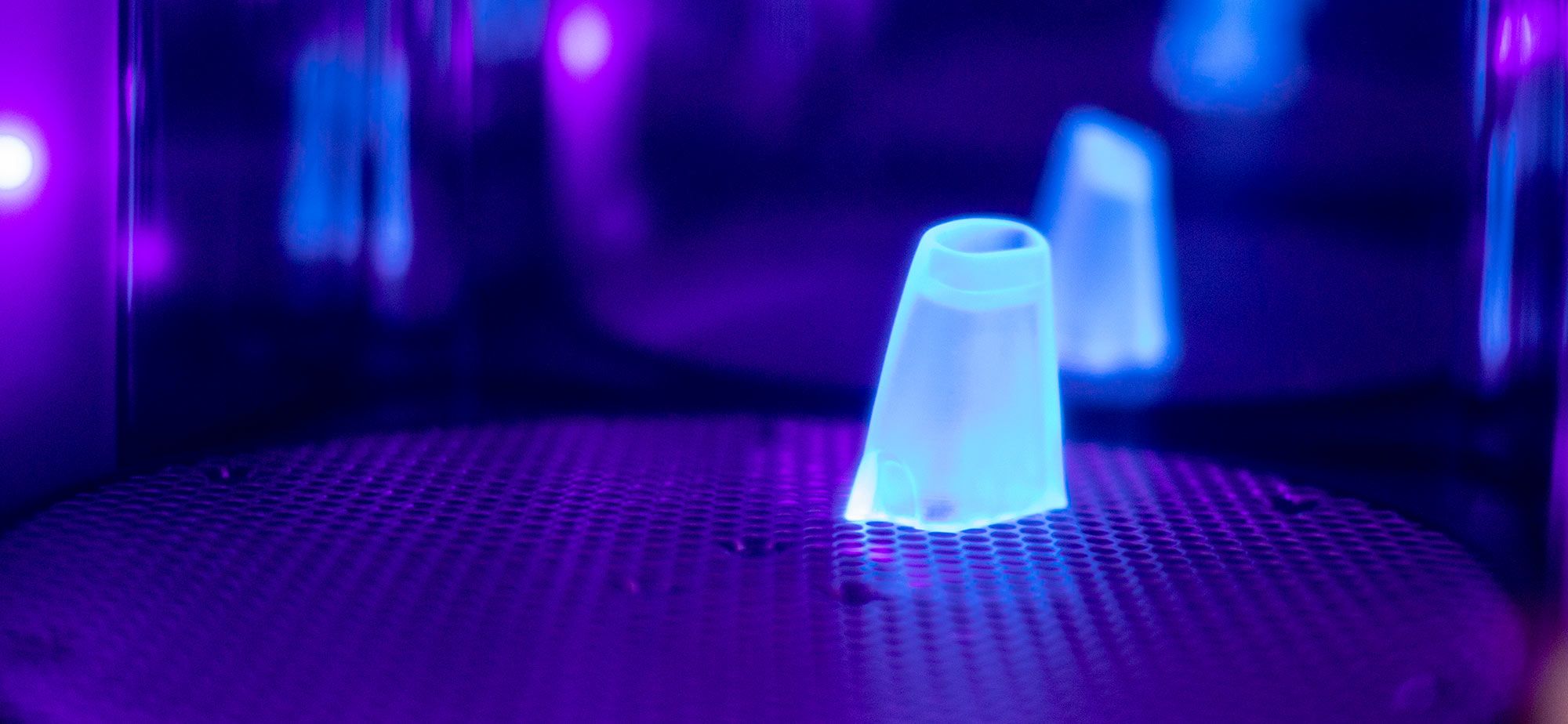

We have expanded our in-house prototyping capacity with a Form 2 3D SLA printer from Formlabs. We have also purchased the automatic washing station to perfect the clean-up of the prints and a UV curing station to fully harden them.

This system can be used for a range of challenges as it has a huge has a library of resins available from standard clear and grey to flexible, elastic, ceramic and high temperature resistant materials.

Adding to our company's in-house prototyping capabilities allows our design team to increase the speed of our process and reduce the time to market for our customers by accelerating design, engineering and testing iterations.

It has been put straight into work with 3D printed prototypes for Speedo and a medical client.

New 3D Printer

Our latest 3D Printer