By using structural foam and sculpting clay, we can create styling models that allow us to explore form and layout quickly and efficiently.

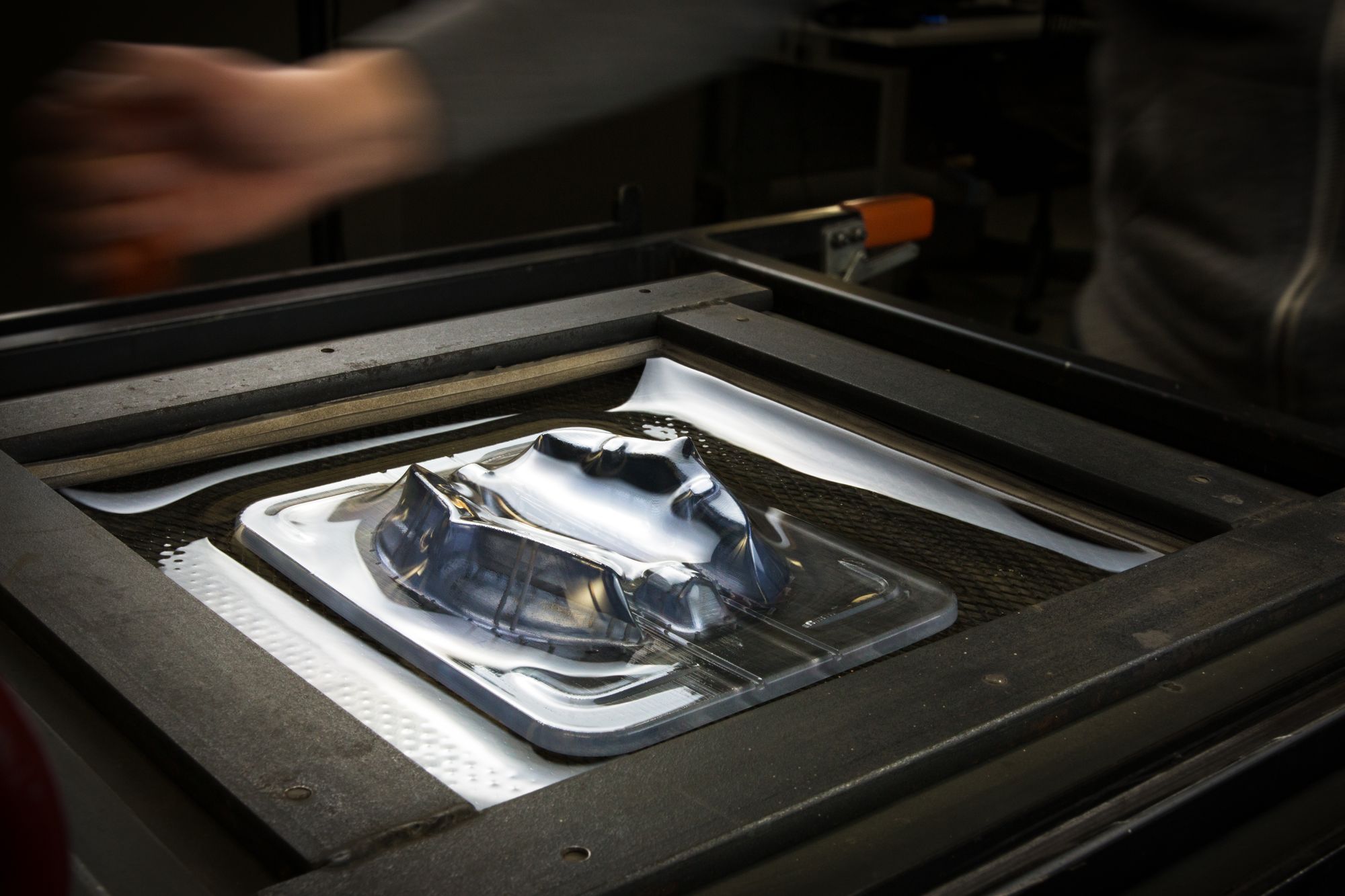

Our hands-on approach to prototyping allows us to perfect the design in real-life scenarios, making it easier to identify and resolve any issues early in the development process. Once we are satisfied with the prototype, we can 3D scan it and bring it into our CAD software for detailed surface modeling.

We also have sanding tables and paint spray booths for putting the finishing touches on presentation-quality prototypes. This allows us to create prototypes that not only look great but also accurately represent the final product. Our workshop is an essential part of our design process, and we take pride in using traditional techniques alongside the latest technology to create high-quality prototypes that meet our clients' needs.