At Raymont-Osman, we are always extending our range of equipment enabling us to test a vast amount of failure modes and scenarios.

Our testing equipment includes:

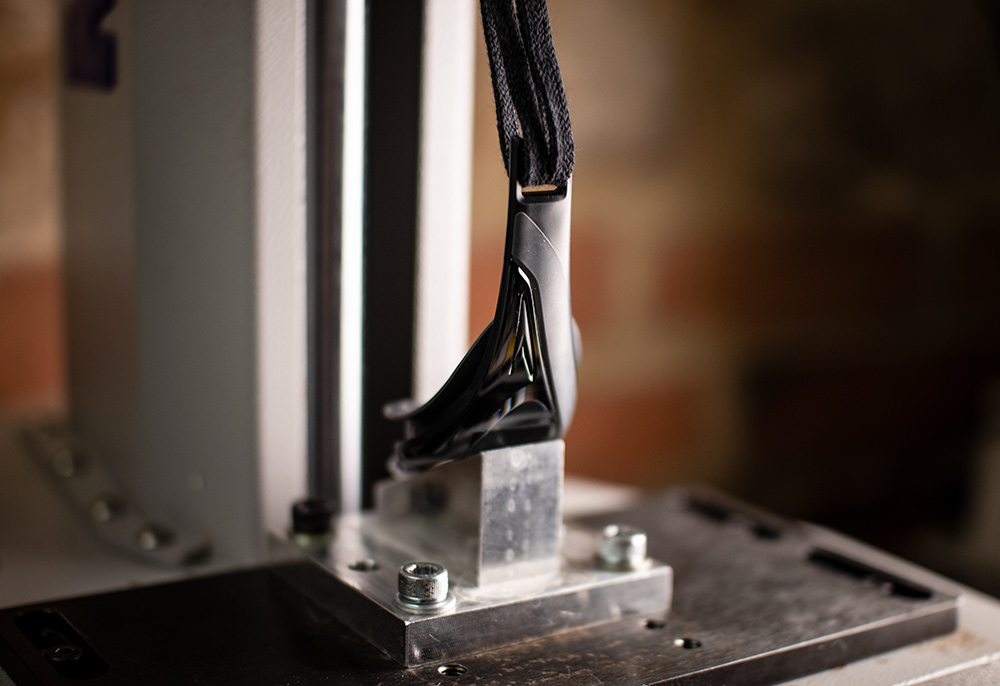

Force Testing - Axial Test Machine

Our in-house axial test machine is capable of applying a tensile or compressive force of up to 2,500 Newtons. This fully-automated machine is capable of lifetime testing both parts and materials. We possess a large collection of test fixtures with the capability to produce any jig or fixture cost effectively and quickly through use of our 3D printer or machining suppliers. The test machine boasts full datalogging capabilities including: the measurement of force, torque, displacement and more. This can validate everything from the haptic feedback of a button press to the ultimate strength of metal components.

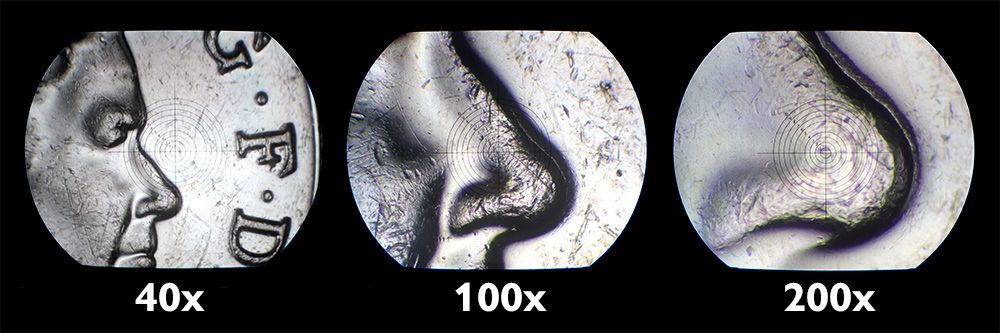

Optical Coordinate Measuring Machine (CMM)

We can inspect the precise size and shape of small parts using our high magnification Optical Coordinate Measuring Machine and Metrology Software. This allows us to reverse engineer competitor products, investigate problems with prototype parts and check the accuracy of production components.

Our in-house Optical CMM has a zoom of 40, 100 and 200 times - ideal for inspecting measurements as small as 10 microns. It is also an excellent tool to inspect the surface quality of test materials. The surface of parts can be inspected for variables such as: stress fractures, galling, wear, corrosion, microscopic debris and more, allowing complete product precision.

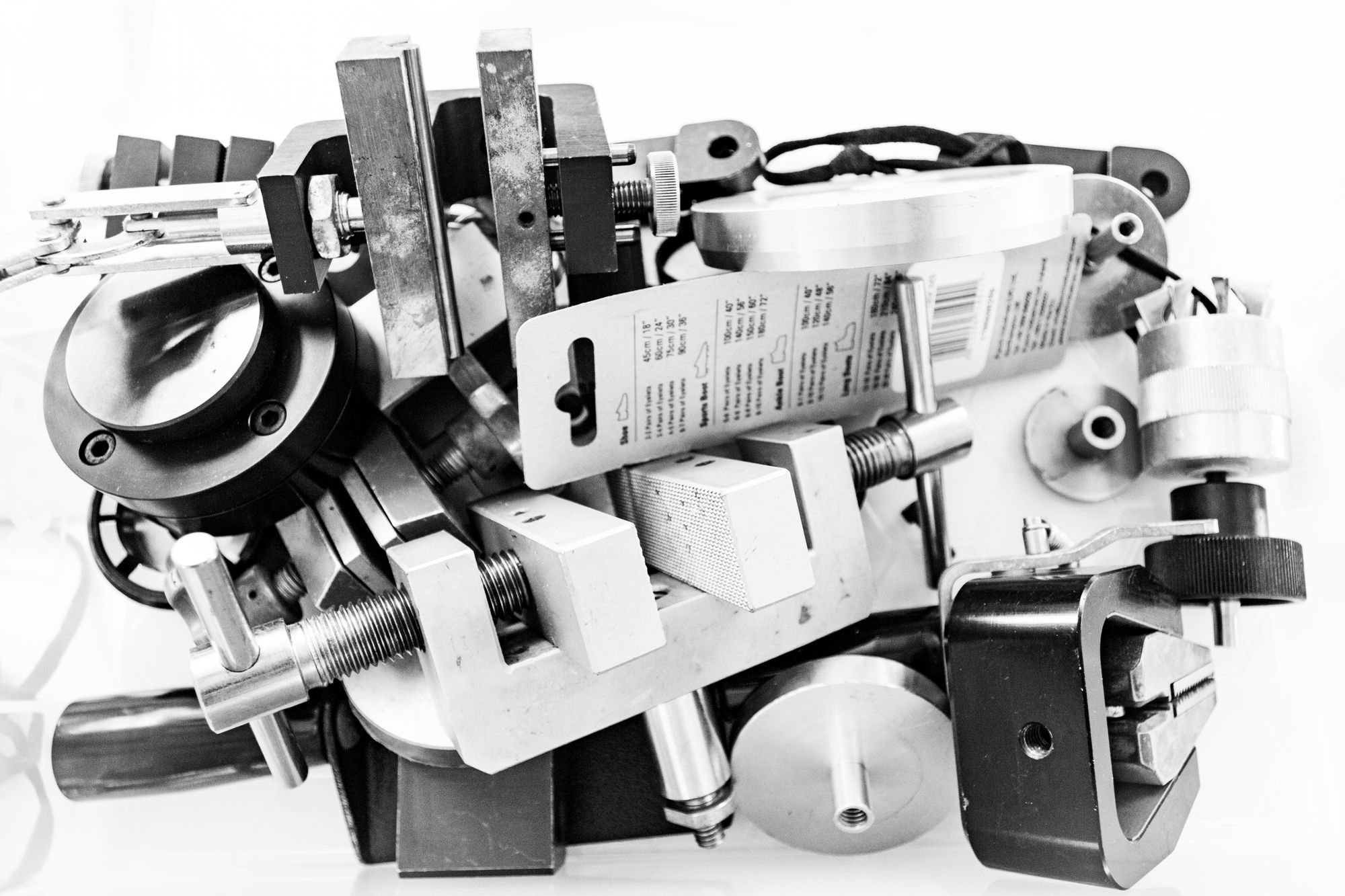

Test Jigs

Our highly-experienced team of Mechanical Engineers regularly build test jigs and fixtures, as well as test parts, using our selection of trusted suppliers as well as our in-house rapid prototyping equipment. Our design lab possesses a full 3D printing suite, meaning jigs and fixtures can be designed, manufactured and ready to use in less than 24 hours.

Electronic and Electrical Test Equipment

Our state of the art lab also contains a wide selection of electronic and electrical test equipment, including a fully mobile datalogging system capable of recording 8 sensors at once. If you have a product that requires testing before entering the market, get in touch and find out how we can help.