Simulation

The Engineering team at Raymont-Osman make full use of simulation software and methods for three primary purposes: Concept validation of a prospective product prior to manufacture Validation and proof of strength of existing products to ensure they are safe and unlikely to fail during normal us Fault diagnosis of products already within the manufacturing cycle.

Plastic Injection Moulding Simulation and Analysis

Designing plastic parts can be a tricky business, as it often involves a significant investment in tooling for production.

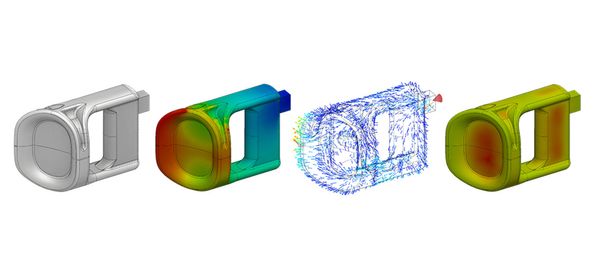

Simulation - Optical, FEA, CFD and Motion Analysis

At Raymont-Osman, we offer a range of virtual simulations and analysis, including Optical, FEA, Injection Moulding, CFD, and Motion Analysis. These tools allow us to save time and costs by identifying and addressing potential design issues early in the process.

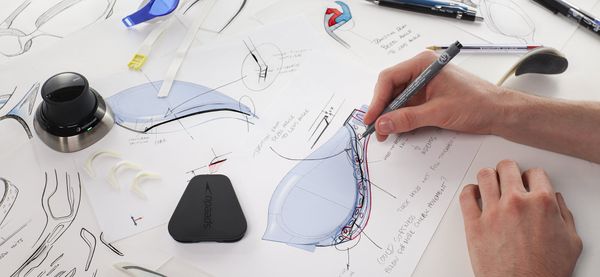

Prototypes

We take pride in our ability to bring your vision to life through the creation of physical prototypes. Our state-of-the-art workshop boasts cutting-edge facilities for handcrafting and 3D printing, enabling us to produce prototypes that are unparalleled in their accuracy and detail.

Simulation in Design

Our wide range of simulation methods will help you when you require validation of your initial idea ahead of development

Product Testing and Analysis

Testing goes hand in hand with Simulation during the design process but more importantly, it allows physical validation of a product before releasing it to market.

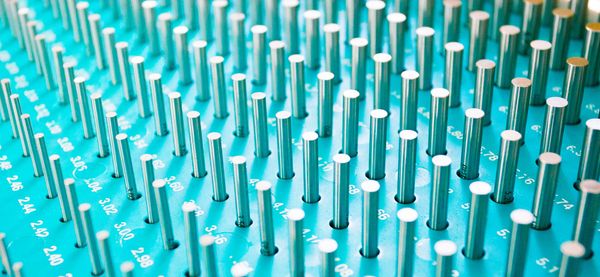

Part Inspection, Validation and Quality Checking

We use high end measuring equipment and a CMM to check your manufactured parts are the right size.

Looking to get started?

We love hearing from creative ambitious businesses and individuals who are looking to make their dream a reality. Take advantage of our free discovery call. A complimentary 30 minute consultation call with one of our expert design consultants. Book Now