Our experienced team of engineers and designers use state-of-the-art equipment and software to provide detailed reports and analysis, including 3D scans, material analysis, and performance testing. With our reverse engineering services, we can help you stay ahead of the competition and create products that meet the highest standards of quality and functionality.

Through Reverse Engineering, we can deconstruct any existing product to learn as much as possible about its functionality and assembly. This can allow you to gain crucial insight into the performance of your own product range and those of your competitors. To begin reverse engineering with Raymont-Osman, get in touch here.

Whether you have a historical part that you need to recreate or wish to know more about a competitor’s product, we are able to supply a wide range of facilities:

Teardown Research

Our team of experienced Mechanical, Manufacturing and Electronic Engineers are familiar with modern and historical methods of manufacture. We can learn a great deal about the design of a product, the purpose of each of its components and features as well as its strengths and weaknesses by just disassembling it. We then feed these key pieces of information back into your new design to create a product that capitalises on its core strengths whilst removing faults and is optimised for manufacture.

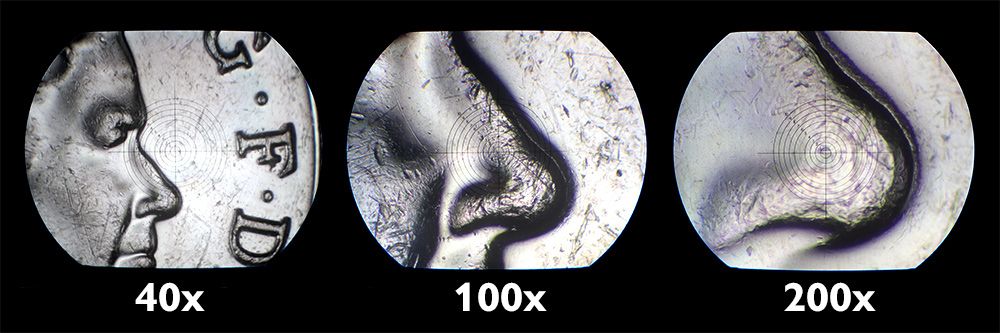

Optical Coordinate Measurement Machine

Our Optical CMM allows us to make microscopic measurements of components, allowing us to create 3D models which are accurate to thousandths of a millimetre. Measuring the thickness of a film or coating is also possible, with the data collated by our CMM feeding directly into our CAD systems to enable our team to analyse and recreate models.

To find out how your product could make use of Optical CMM, contact us here.

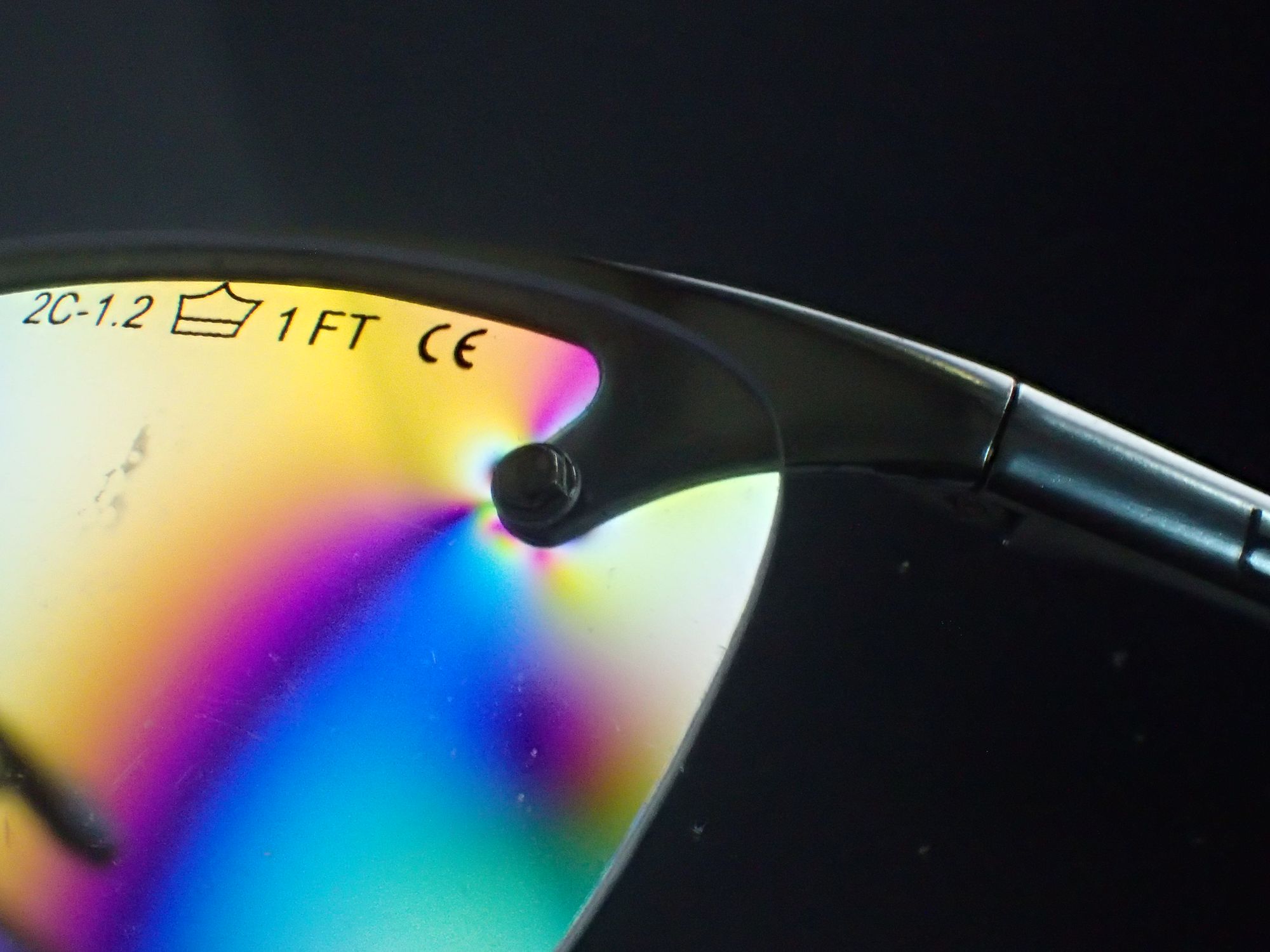

Polarised Light Testing

Whether as part of a redesign of an existing product, gaining an understanding of a product faults and returns, or as part of the analysis of the strengths and weaknesses of a competitor product, our Engineers are practised in employing a range of polarized light techniques to help you to ascertain the properties of materials. Examining components in this way enables us to determine a whole raft of features - from assembly stresses, injection moulding flow lines to residual moulding stresses.

Light is an electromagnetic wave. Despite being able to vibrate in multiple directions, light waves tend to be described as vibrating in two directions at right angles to each other. Where light vibrates in different directions, it is referred to as ‘unpolarised light'. 'Polarised light' conversely represents a light wave that vibrates in a single direction. Key is the fact that humans are not sensitive to the direction of vibration of light. Using our specialist equipment, our team uses two polarisers at right angles to one another to highlight the hidden properties of materials.

When the polarised light interacts with the crystallinity of the polymer, it is distorted and refracted, that when repolarised, creates a rainbow of colour displaying the stress patterns in that material. The more dense the colour contour change, the more significant the stress upon the material.

Polarised Light Testing literally allows us to view the invisible, optimising design and circumnavigate the potential pitfalls of materials and processes. It also allows us to compare physical samples to injection moulding simulation results - enabling us to calibrate theoretical to real-world parts and producing more realistic simulations next time.

Experiencing faults with your existing product? Want to perform better than a competitor product? Contact us for expert insights and solutions to perfect and optimise your product and gain a competitive edge in the market.

We have also partnered with leManoosh to create engaging teardown tutorials that provide an inside look into various products. Discover the design and engineering intricacies of different products to gain valuable insights for your own product development projects.