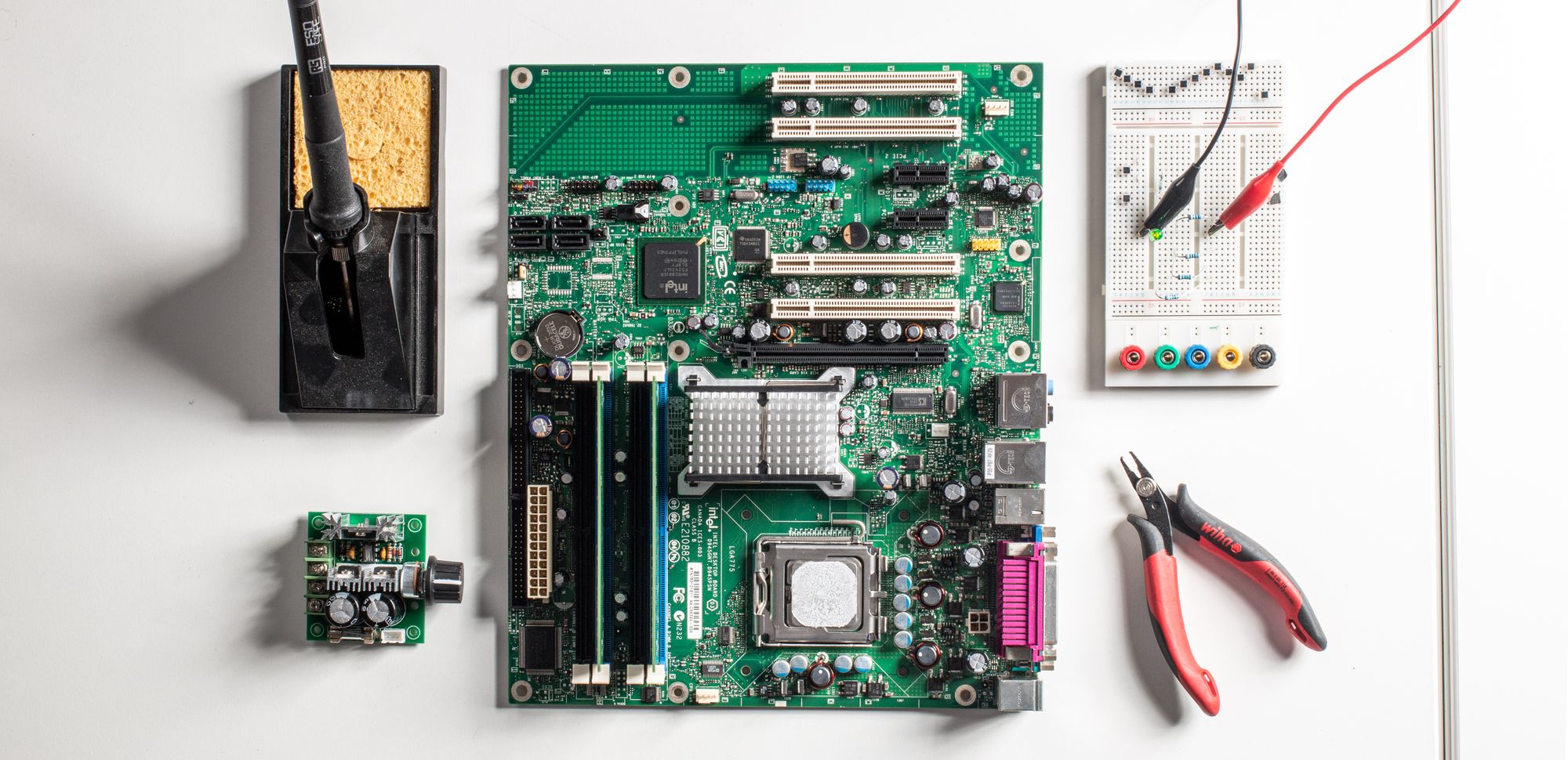

Early stage Electronics prototypes are constructed by hand on plug-and-play bread board, development boards or manually soldered together. However, for production, you will need carefully designed electronics modules constructed on Printed Circuit Boards, PCBs.

These PCBs make the electronics much smaller while improving quality and consistency. For low volume production, these can be hand soldered or manually placed and reflow soldered. In large volumes though, automatic pick and place robots collect individual chips, transistors, capacitor and resistors and precisely place them on the blank PCB. This is a very fast and accurate process and vastly reduces the cost of assembling large quantities of PCBs.

The Electronics Engineers at Raymont Osman Product Design Consultancy use the cutting edge software Altium for PCB design and realisation. Components can be added to libraries, positioned on virtual circuit boards and the connecting tracks routed between them. These designs can then be checked, refined and sent out for manufacture as a Gerber file.

Another benefit to using Altium is that the circuit boards, with all their components in the right place, can be exported as 3D geometry into SolidWorks enabling the Mechanical and Electronics Engineering to happen at the same time.