“Great design is the iteration of good design”, M Cobanli.

The iterative process is often called “rapid prototyping” or “spiral prototyping”. At Raymont-Osman, we don't employ "Designers". All our staff work in BOTH design and development: this is crucial in tightening up the iterative loop necessary for design. This is unique in the field of Product Design Agencies and a conscious decision by Team RO. Here's why and how it benefits our clients...

It all begins with a simple concept.

To get a product from concept to launch, you will need to iterate many times. As a client - individual or business - you will have spotted a niche in the market. Your user has been identified and you may have conducted some user research.

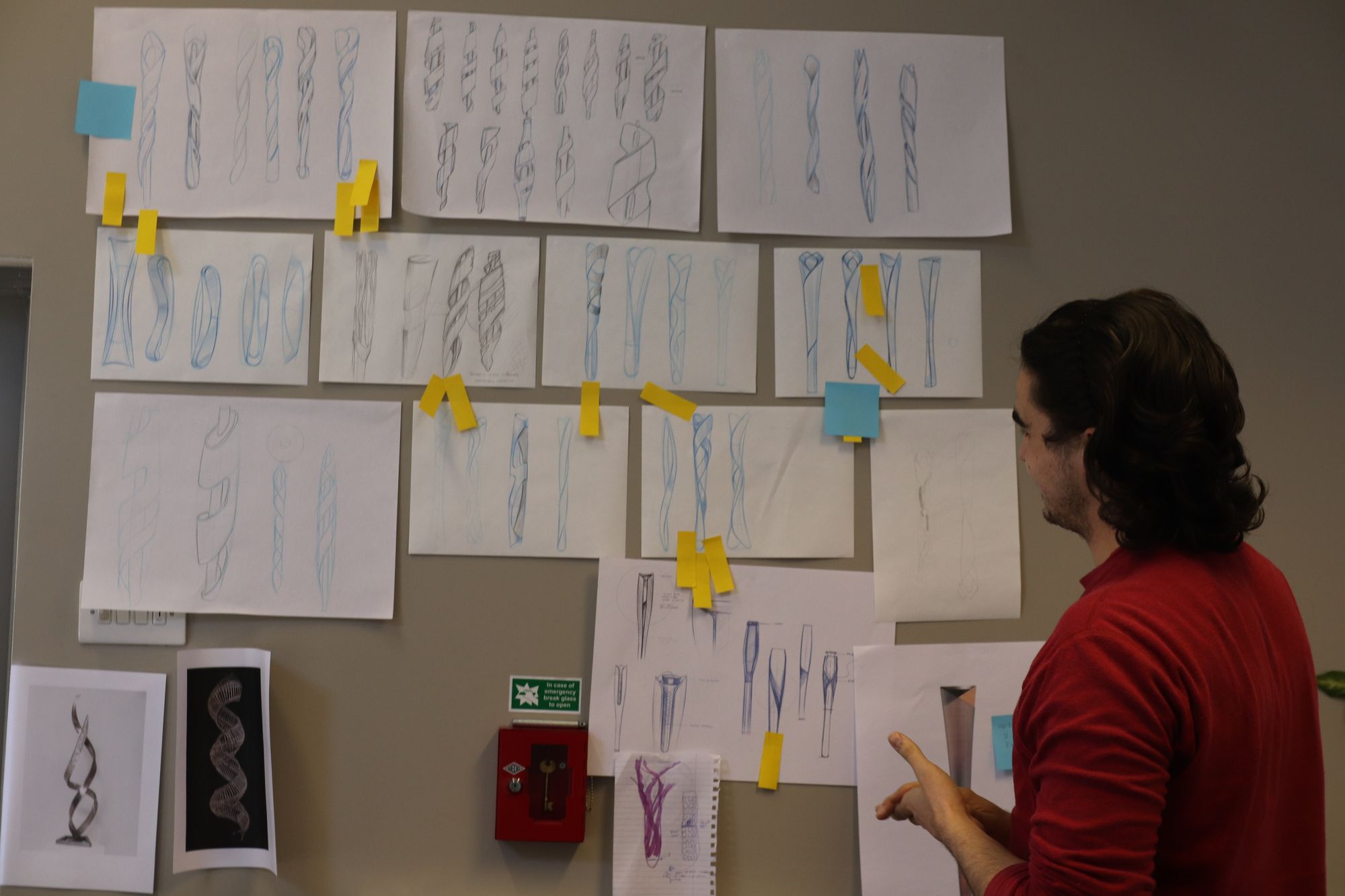

Step 1: Design

This is where we come in....How will your product actually work? What will the aesthetics be? The most important thing to note about this stage is that it is just the beginning of the product journey: stopping here and rushing straight into manufacture is a big 'no, no'....

The danger with 'designers' is just that - they are designers.

People who only work on the design aspect of a product never learn about what is good and most importantly, what is bad about a design. As such, they do not directly suffer the consequences of a poor design - as a result, the design does not get any better. Mistakes are repeated time and again, at unnecessary cost to the client, the consumer, and (if we are honest!) the design agency.

Quality, well-considered design for manufacture (DFM) is essential.

Step 2: Test

Design validation is key.

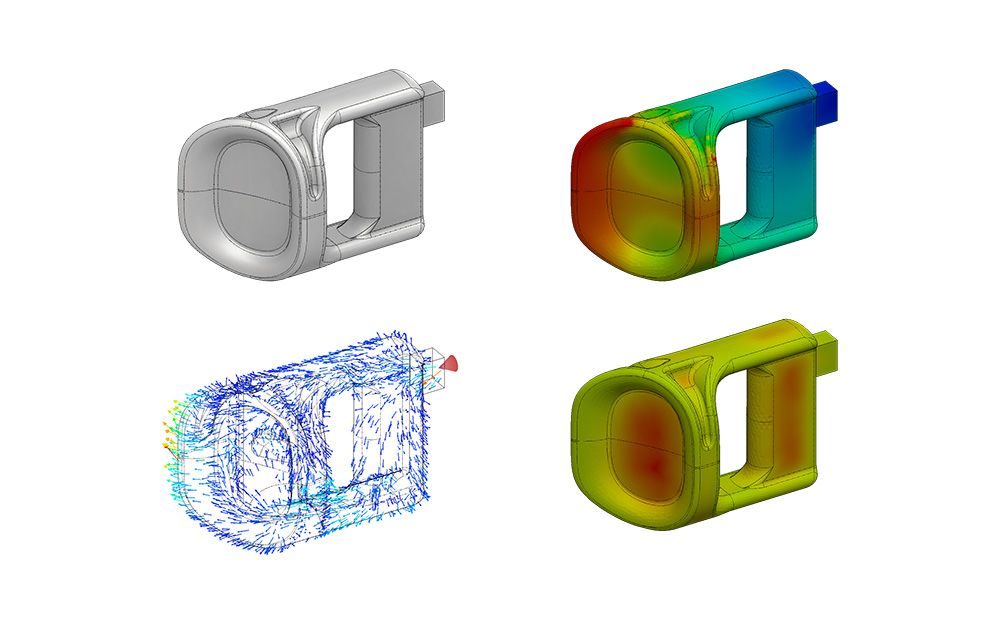

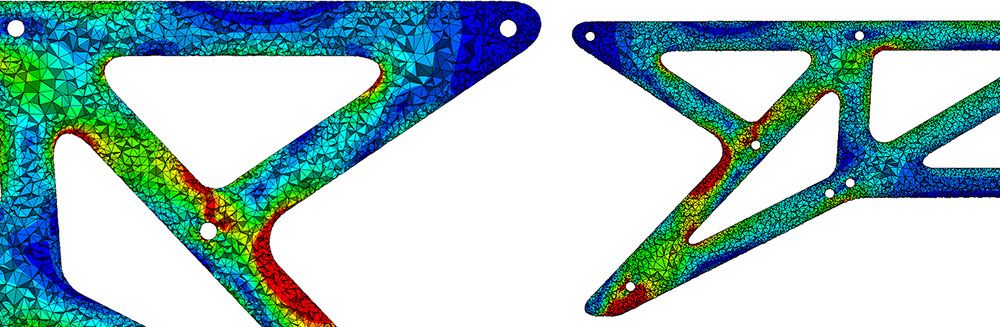

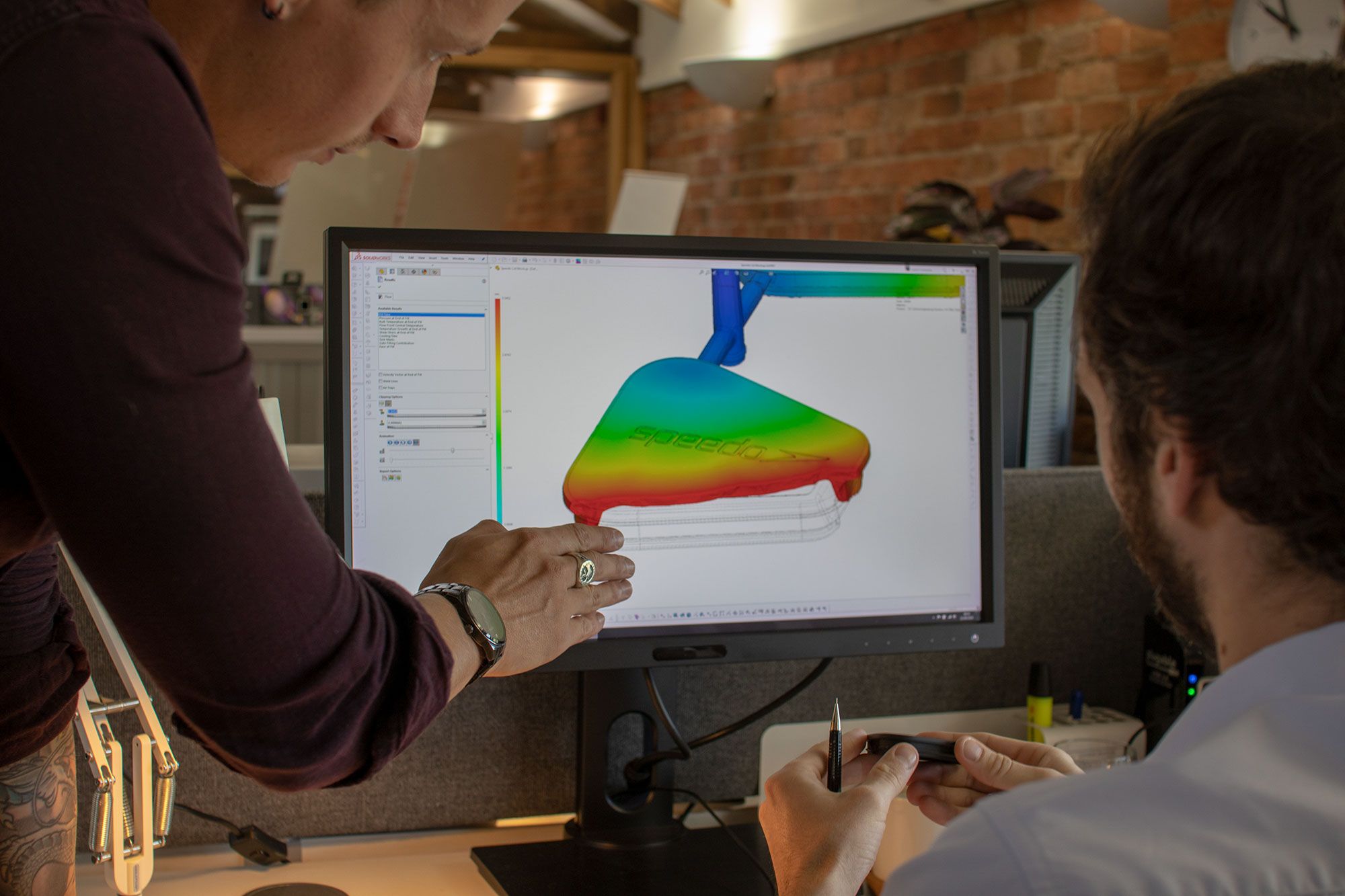

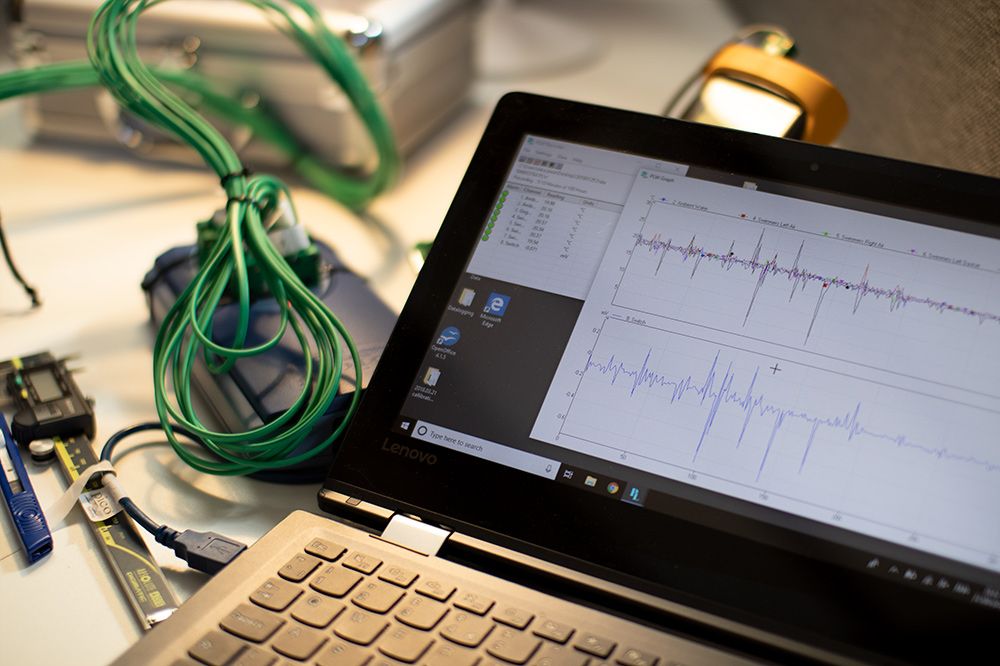

Even before the prototyping stage, we are able to run complex simulations which are able to provide data on a multitude of design considerations; from injection mould simulation to kinematic simulation.

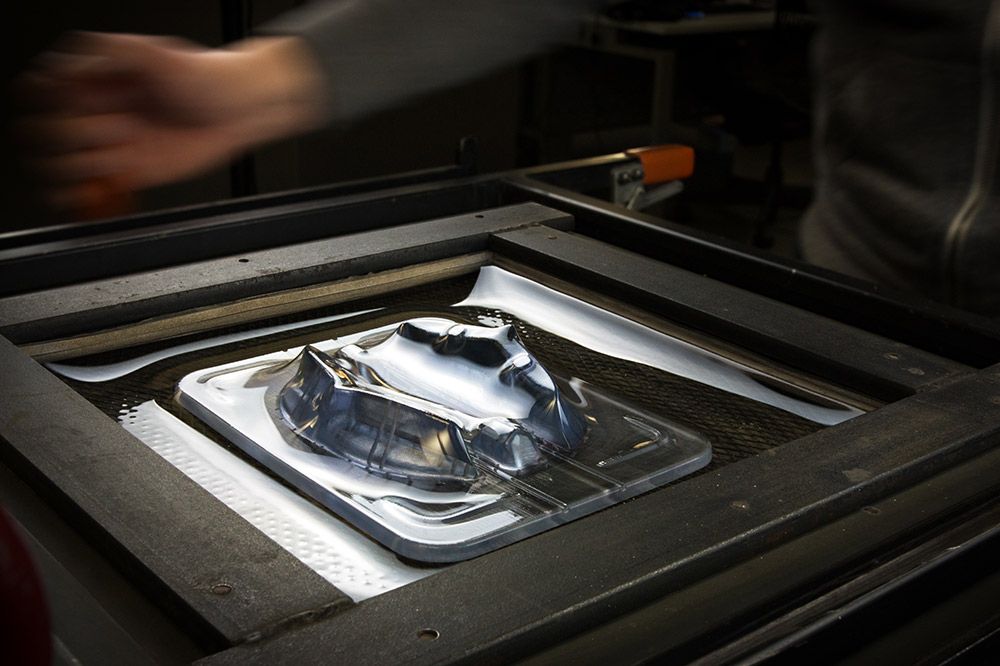

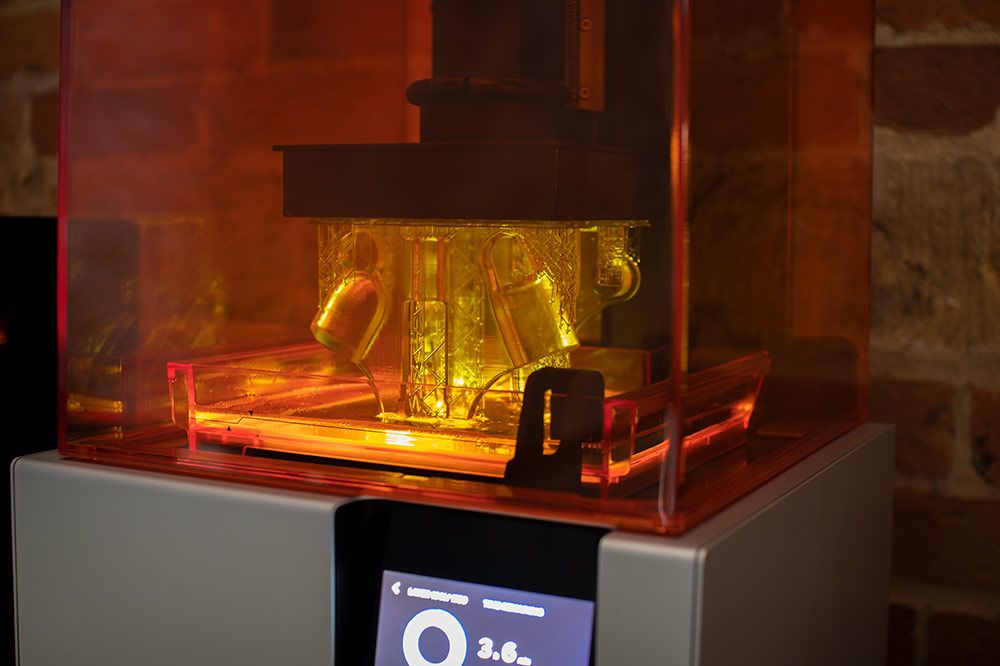

Following on from this is the production of the first prototype/s. The RO design studio is fully equipped with the latest cutting-edge 3D printing technology, which allows us to produce prototypes around the clock in order to maximise time efficiency. 3D printing is just one of the many tools in our box that enable us to do this.

Once a prototype has been generated, it should be put through rigorous testing in order to identify where the initial design can be improved.

Again, our workshop contains a wide range of testing equipment which allows us to measure performance - from force testing to drop testing, user testing and software testing.

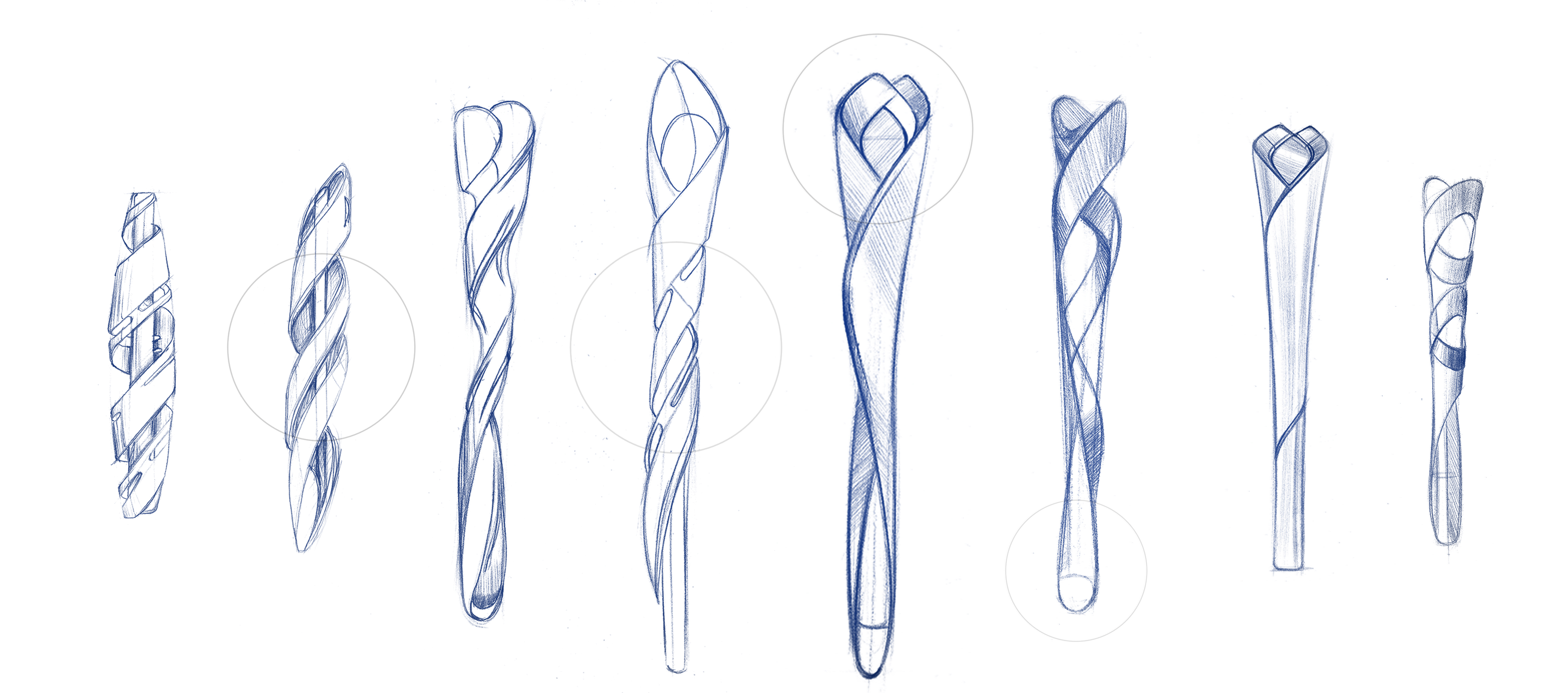

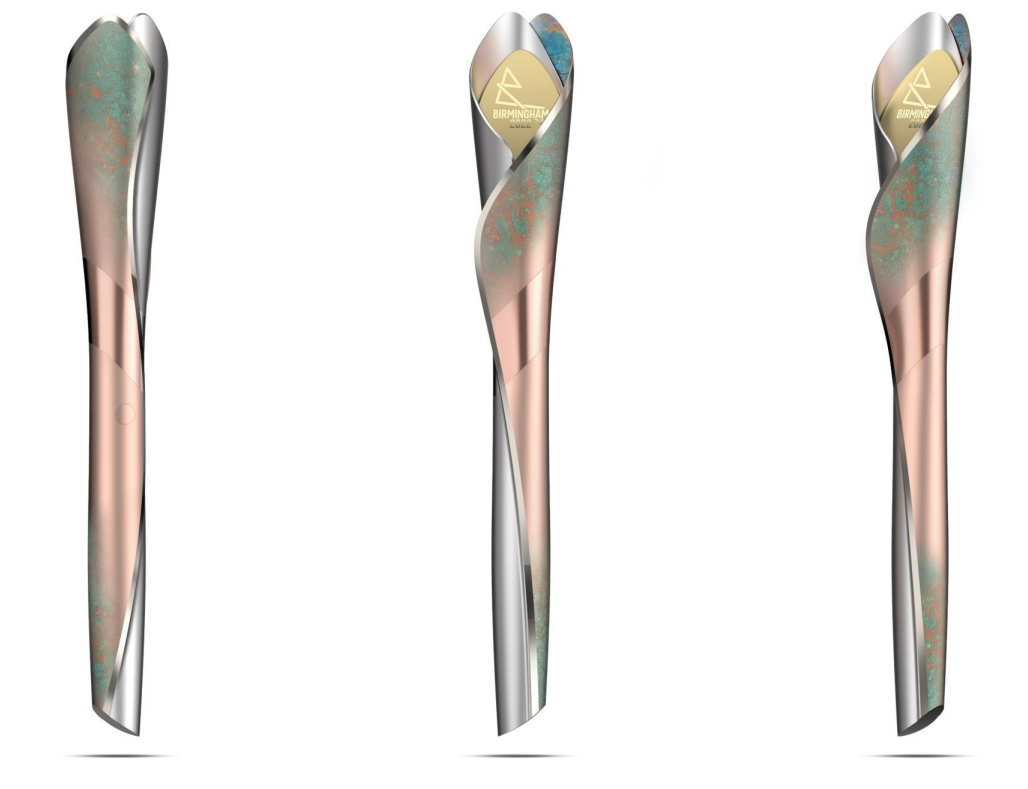

The great thing about prototyping is that it is comparatively inexpensive and quick exercise. Prototypes can range from 3D prints to one-off builds. At Raymont-Osman, we have even worked with an empty Pringles can as a placeholder to build electronics for the Birmingham 2022 Commonwealth Queen's Baton!

Prototyping allows us to investigate several competing concepts and ideas in order to evaluate which one should be further developed, without having to invest heavily in what turns out to be a redundant design.

Step 3: Refine

So, your prototype has been tested and the design evaluated: it's now time for refinement.

This is where we take what we have learnt during the testing stage and amend the design according to our findings.

Step 4: Repeat

Following the refinement stage, we are ready to create a new prototype.

This stage tends to focus on one, distinct design which has typically come out strongest from the testing stage.

From here, testing is repeated and the process continues with further refinement until the loop is closed and the design is considered ready for manufacture.

Get a design wrong and the potential outlay can run into the tens and hundreds of thousands - from new and expensive tooling required to make your product, to recalls and redundant stock, this is not a risk clients can afford. Through participation in the full iterative loop, our team can anticipate problems, solving any hiccups quickly - avoiding the time delays and significant costs of redesign further down the line.

Raymont-Osman Iterative Loop Case Study: Queen's Baton, Birmingham 2022 Commonwealth Games