Since the emergence of formalised Industrial Design practice, modelmaking and prototyping has been considered to an indispensable tool for professional Designers. A method of demonstrating form, fit and function before a product moves into production, model making enables Designers to explore designs in physical 3D form. Carving out foam, sculpting clay, working with cardboard or 3D printing may seem initially seem primitive but, in reality, the value of model making as a product design process should not be underestimated.

Three Dimensional Sketching and Accessible Design

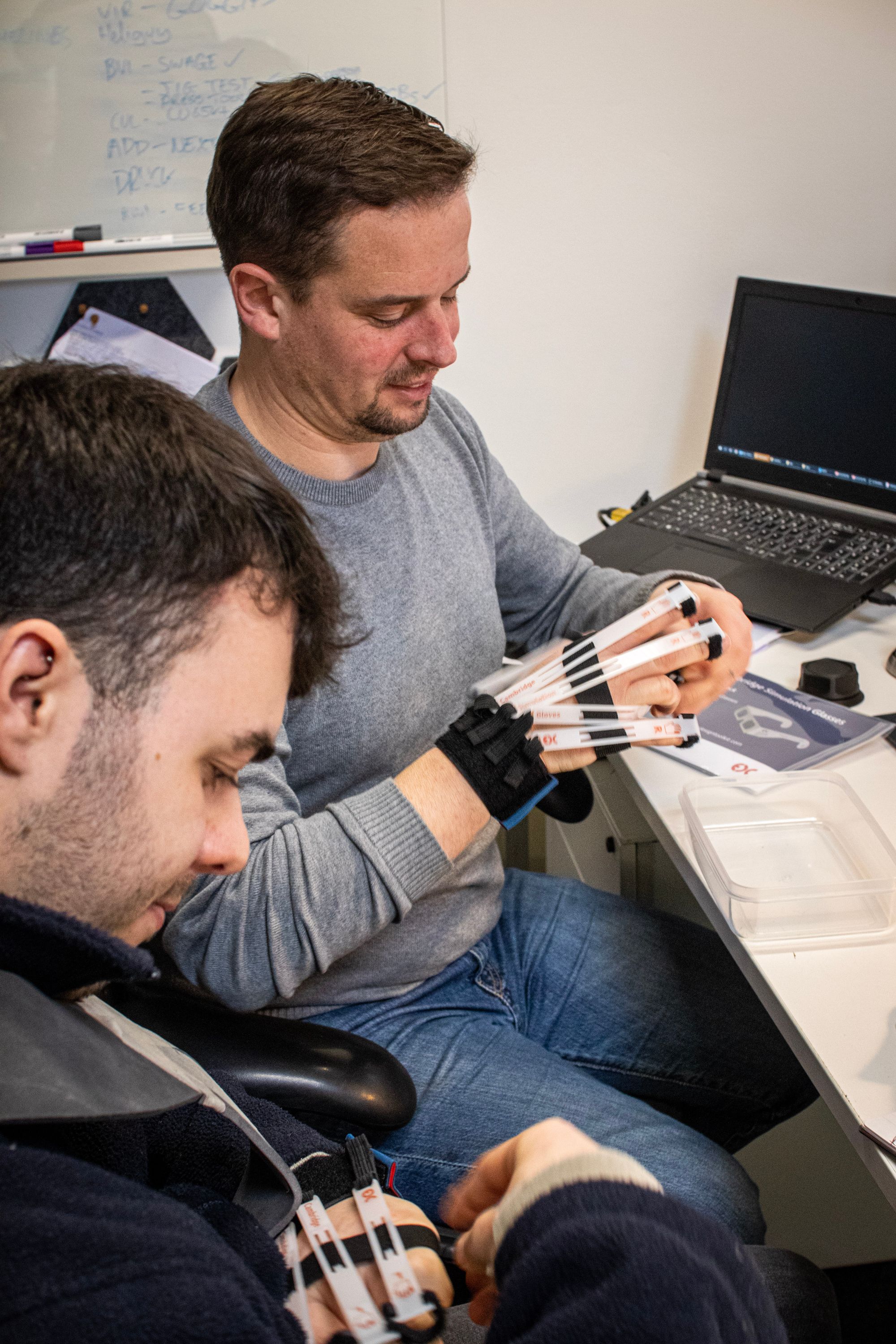

Through the creation of models, early-on within the initial design process, Designers are able to reach a deeper understanding of concepts. Put simply, model making is really just 3 dimensional drawing! Models are not there to be pretty - they are part of a work-in-progress. They can be crude, rough and ready. Most importantly, they are a tool for answering design questions and generating answers - or sometimes, new questions. Model making is an invaluable process which enables our RO Designers to visualise concepts in physical form, test various aspects, for example, the position of a dial or the feasibility of a switch, simulating the feel, and any potential problems for the end user. At Raymont-Osman, we also have extensive experience testing out our designs using reduced-mobility gloves and vision-impairment simulation glasses to ensure accessible, socially-responsible design. To certain products, this universal accessibility can mean success or failure.

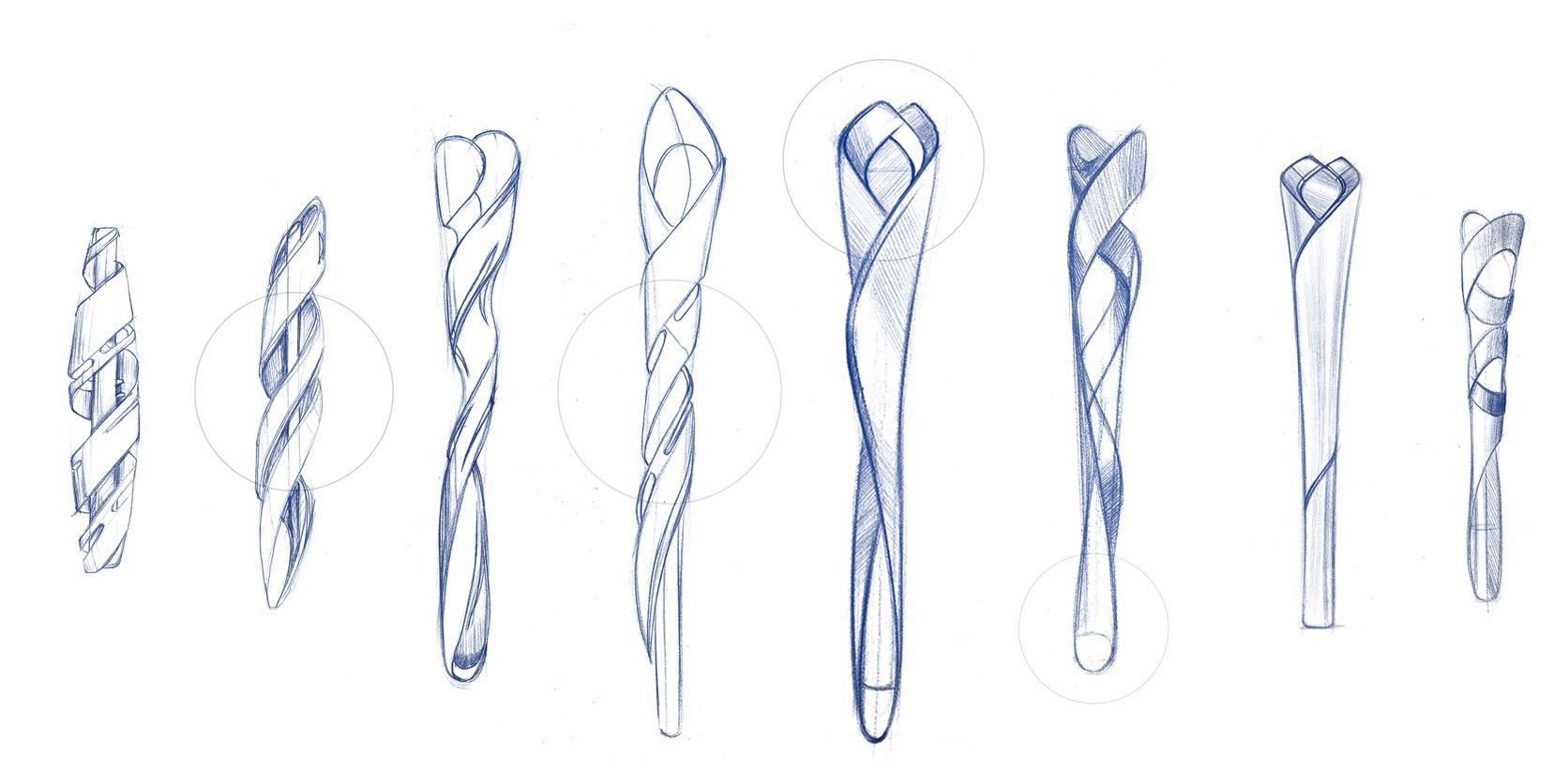

Model making is divided mainly into three key areas: functional, ergonomic and aesthetic models.

· Functional models ('works like') provide the essential and characteristic features of a product. They are used during the development of the design to check and develop new and innovative functions including features such as switches, dials, overall product size etc. These are often not pretty to look at, but serve the role of simulating the basic functions of the product.

· Ergonomic models ('feels like') allow designers to evaluate whether a particular form / design is easy to use and can be used interpreted by the end-user as desired. It involves the customisation of form to meet specific user needs.

· Conversely, aesthetic models ('looks like') are often created in order to test and evaluate the visual features of a design.

All three types of models form critical aspects of the prototyping phase, and an opportunity for user study into form and function necessary for future iterations of the design.

Communication is Key

Modelmaking is also an essential tool for effective client communication; ensuring a deeper understanding between Designer and client. Many of our clients, and indeed the general population, find it challenging to visualise what a product will actually be like in reality from purely looking at a simple 2D sketch. How will it feel, work etc? You really can't beat physically placing a 3D model in the hands of the customer! From here, aspects such as size, ergonomics, location of features such as dials and buttons etc, can be evaluated and improved upon in a way that can't be appreciated from a concept sketch.

Testing Intuitive Design

Intuitive design refers to all considerations aimed at making products easy to use, without the need for lengthy instruction, help or effort. Indeed, good design often does not even require conscious thought from the user about how a product should be used.

A good example of effective intuitive design is the computer mouse or a games controller.

One of huge benefits of model making is user-testing of intuitive design, especially when users' interactions with the product do not go as expected eg. holding a device upside down. From here, a Designer can determine future, important design iterations - in this case, the incorporation of directional cues, such as the curve employed on a computer mouse which follows the natural shape of the hand.

Low Risk, High Reward

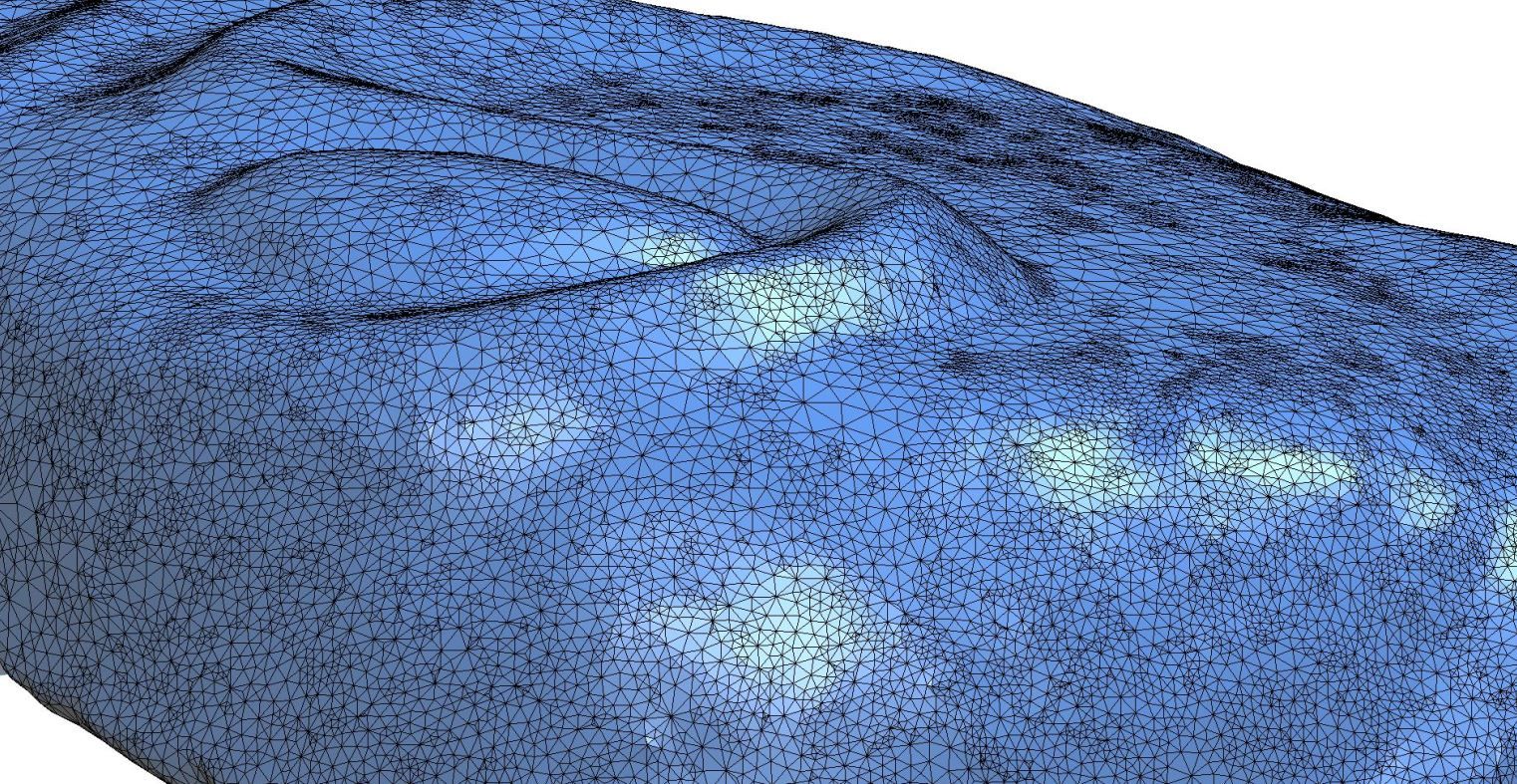

Model making is hugely advantageous as a low risk, high reward design strategy. CAD (Computer Aided Design) can have limitations, particularly when modelling more organic forms - often requiring immense skill and hours of painstaking work. All of this for the design directive to suddenly change or significant iterations be required. In contrast, modelling is relatively quick and cheap. Complex, organic forms can be created with little effort. In short, clay is much easier to manipulate than CAD!

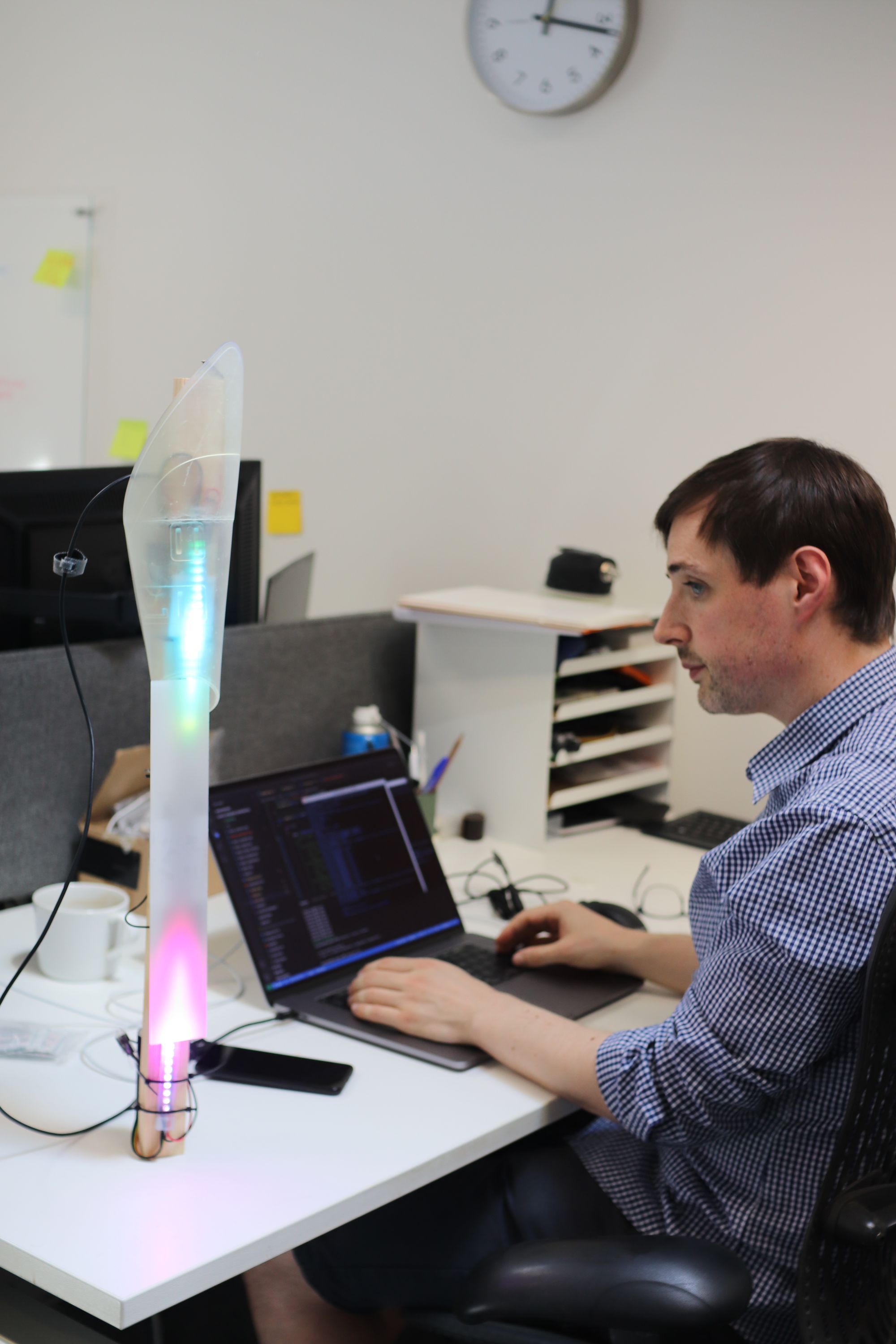

Once a design has been agreed upon, our Designers digitally scan the physical model using photogrammetry - the process whereby 3D information can be extracted from photographs of a 3D object (in this case, the physical model). These photographs are subsequently overlapped, converting them into accurate 2D digital models. This can then be imported into SolidWorks and used to produce a computerised 3D model ready for manufacture once the design details have been finalised.

Design Validation

The tooling used to manufacture a product can often run into the hundreds of thousands of pounds - last thing a client needs is for post-sign-off design changes, rendering this investment useless. At Raymont-Osman, we often make use of 3D printing technology as part of the crucial process of design validation: do the components actually fit together? Is this obvious to those assembling it? General ease and speed of assembly. Are there any hidden mistakes in the tolerances? Through modelling, all of these risks can be ascertained and mitigated out of the design before costly investments in tooling are made - not to mention the costs associated with the time delays involved should manufacture prove unviable.

Pre-Launch Marketing

Raymont-Osman clients often need to market their products in the run-up to manufacture. This can be for a variety of reasons, but most often, the major motivation is securing funding for the next stage of their product's journey; whether from a private investor or as part of a major crowdfunding campaign. Either way, there is often a need to communicate abstract ideas into something more concrete in order to get others on-board in advance of the launch of a product.

Here, modelling really does come in handy. The combination of a good 'looks like' / 'works like' model can easily be made into something sufficiently presentable for product photoshoots or promotional videos aimed at seeking funding. A skilful modeller and a can of spray-paint can be a powerful thing when seeking funding for the next stage of development or manufacture. Using modelled 'props' also brings with it benefits for clients wanting to create images that can’t be generated in real life, such those featuring large groups of products within a range. Fly-throughs, assembly videos, key features and specific movements are all possible in lieu of a finished product. The sky really is the limit!

Whether used as part of the market research, use-panels, prototyping process, assessing manufacturing viability or as a promotional prop, model making is a crucial component in many product journeys.