Designing a product can be a fun, rewarding and profitable experience. As a leading product design consultancy, we’ve taken many great products from just an idea, to a production ready product for our clients. This article looks at the five steps we use to design a product and the product design process that we use to do it.

We will look at these steps from that design and engineering viewpoint, so we won’t consider the monumental marketing efforts that our clients go through, such as: finding buyers, choosing a distribution method (Amazon, Walmart), marketing, advertising and even ordering stock. Instead, we’ll examine how to find and produce the right product.

1. Identify the Problem

Starting with a problem (and not the solution) is the secret to better selling products. It’s too easy to say “I want to make a new shoe” without considering whether the world really needs a new shoe (it probably doesn’t). It’s much better to say, “My feet hurt after standing up all day at the store.” Why is this? Firstly, you have identified a problem - your feet hurt. Secondly, you have identified a target market - employees in retail stores. From here, yes, you could go on to explore concept shoes, but you could also look at seats for employees at the store. Both would solve the problem for that audience, both have high demand but one may have much lower competition.

When you can’t experience the problem yourself

There are many situations when you can’t experience the problem directly. Perhaps you work in diabetes care, but (luckily) you don’t have diabetes. Perhaps you work for a swimwear brand but you don’t swim. Perhaps you live in one country but design for people in another. In that case, finding insights into the problems that people face is going to be harder, and take more research. There are many research techniques that can be used but they broadly fall into three areas:

- Market research: go and talk to people and film them in action

- Competitor reviews: experience competitor products, look at the reviews on Amazon, etc.

- Market trends: look at new technology, new materials, new purchasing patterns: are people, for example, going online to get cheaper prices

Identifying the problems that people face in these circumstances can be challenging - what people say and then actually go and do are often very different.

Judging which problems are worth it

There are many problems, or opportunities, in the world that need to be solved. How do you decide where to focus? Which problems are worth solving? The answer is simple; you choose the idea with the highest demand and the lowest competition that will also be profitable.

- High Demand: How many people have this problem - are people searching for it on Google?

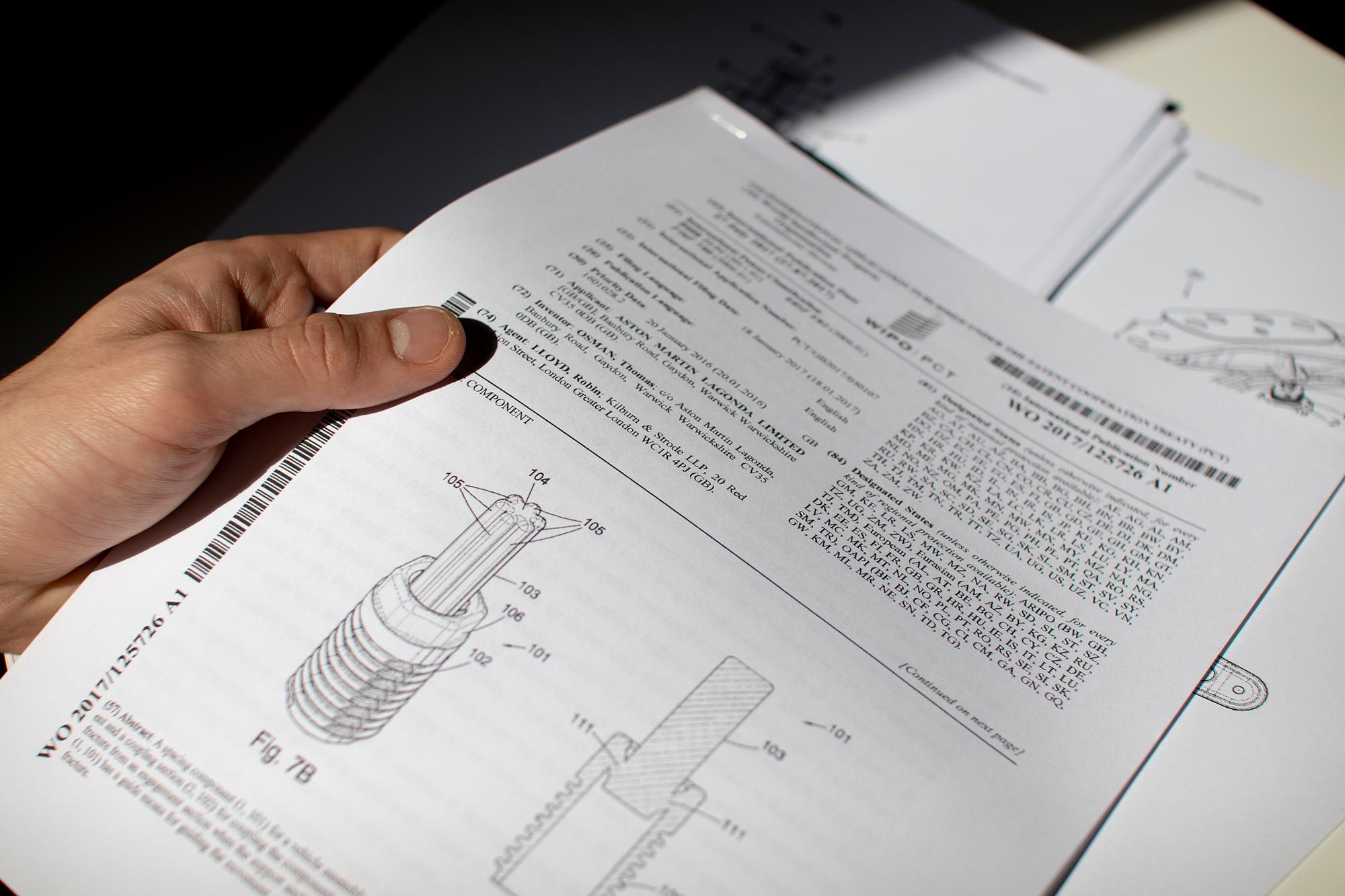

- Low competition: conduct patent reviews - are there loads of competitor patents, is Amazon’s warehouse full of products that do the same thing?

- Good profitable margin: are people willing to pay more for the product than it would cost to make?

Ultimately when choosing your idea or niche you want the strongest Unique Selling Point (USP). You want to stand out in the market and be different from your competitors, while also solving problems that they’re facing. This is what all the best brands do, from Nike to Apple. Through good design and engineering, they create products that are unique and valuable.

2. Concept Design

Good concept design tries to find different solutions to a problem. It doesn’t really matter how it’s done - perhaps a board of post-it notes in a workshop, sketches on the back of an envelope, prototypes or even acting out the problem. What does matter, though, is to think outside the box and not to focus on the first idea that comes to mind.

It’s always easy to dream up expensive and complicated ideas (there’s probably an app for that). Ask yourself, how can we make a simple solution to this problem? How can I make a cost effective solution? A good rule of thumb is to find at least one high-tech (high-risk) solution and one low-tech (low-risk) solution to take forwards. The contrast is what is important here to make the best ideas stand out.

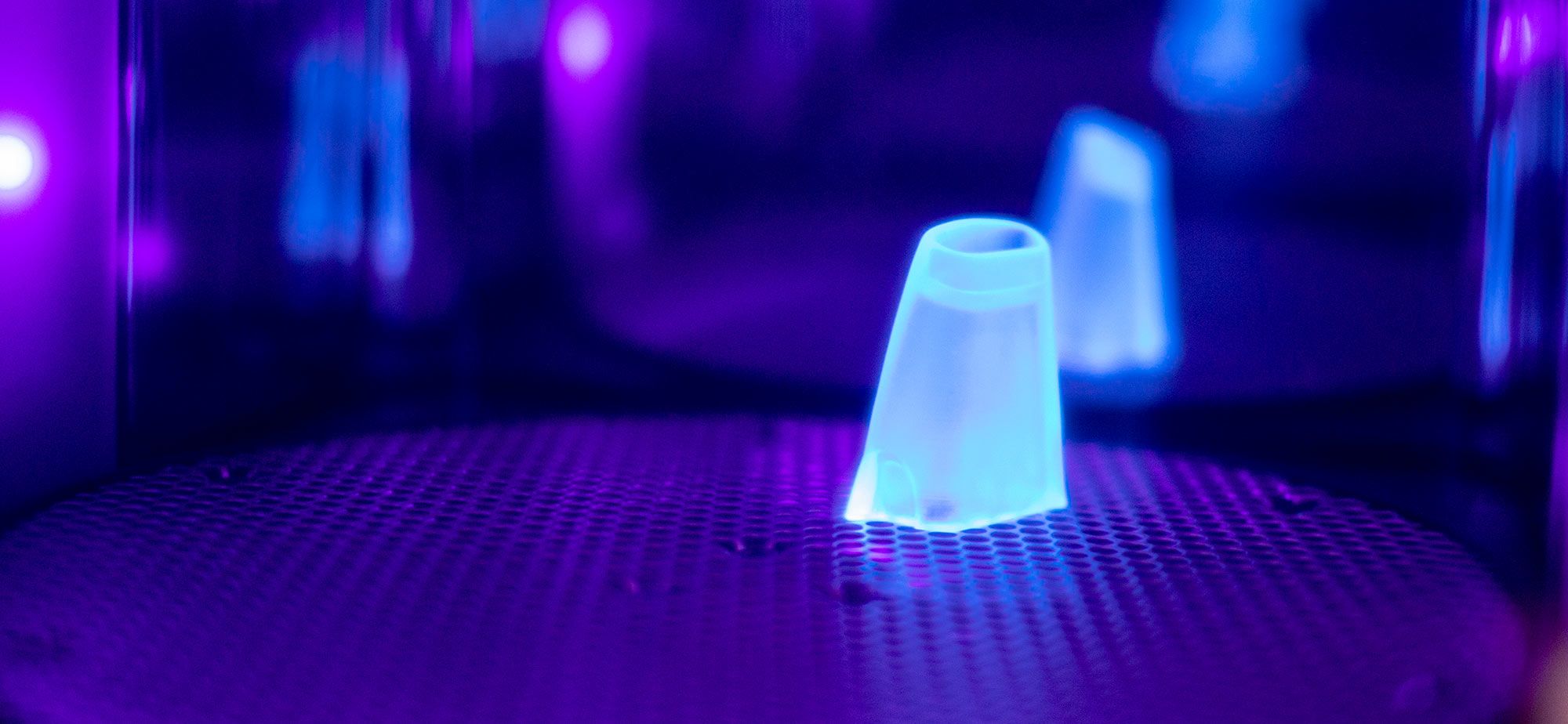

Prototype and test

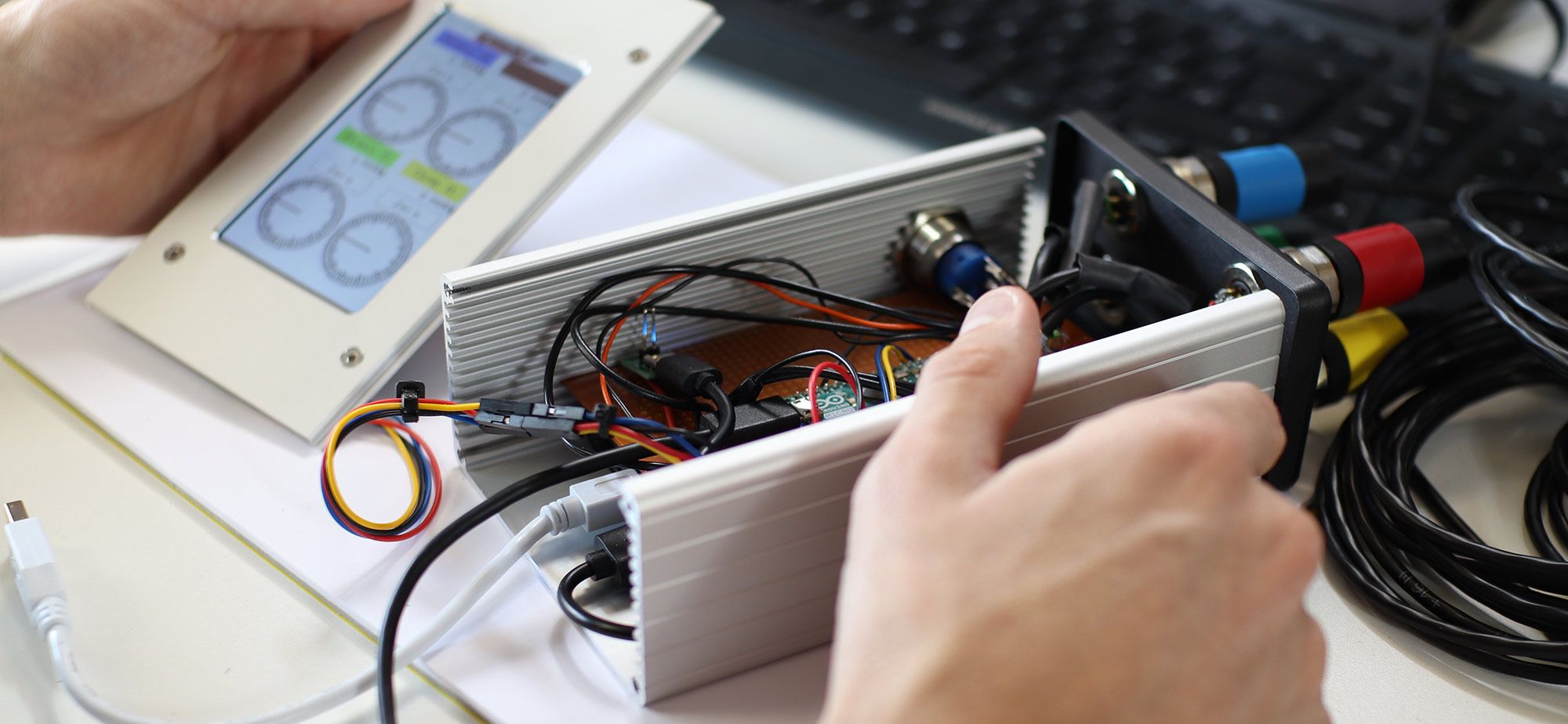

With some concepts at hand, it's important to test them. This can be done in many ways. Perhaps build a mockup, 3D print a design, or visualise and render the design in CAD (a ‘looks-like’ visualisation). It’s also very common to make a proof of concept (works-like) rig to test a technology or interface.

Testing at this stage is critical - either it gives everyone the confidence (and the data) to continue or it signals to pivot to something new. Hopefully, if there are multiple concepts, it simply narrows the field down to the best ideas.

Finding the right product

From a customer’s point of view the right product is simply one that works well, that looks good and has good value (ie. offers the best features for the price). The right product is, ultimately, the one that will improve the lives of the people who buy it.

But from a business’ point of view, it’s also important to make a profit. ‘Working well’ and ‘looking good’ are easy to grasp (if not a bit subjective), but the simple fact is that the product must have a price point that people are prepared to pay and which generates a profit for a business.

It isn’t always easy to get the balance right, but it is more important than ever to get good reviews on Amazon by creating great products.

3. Design Development

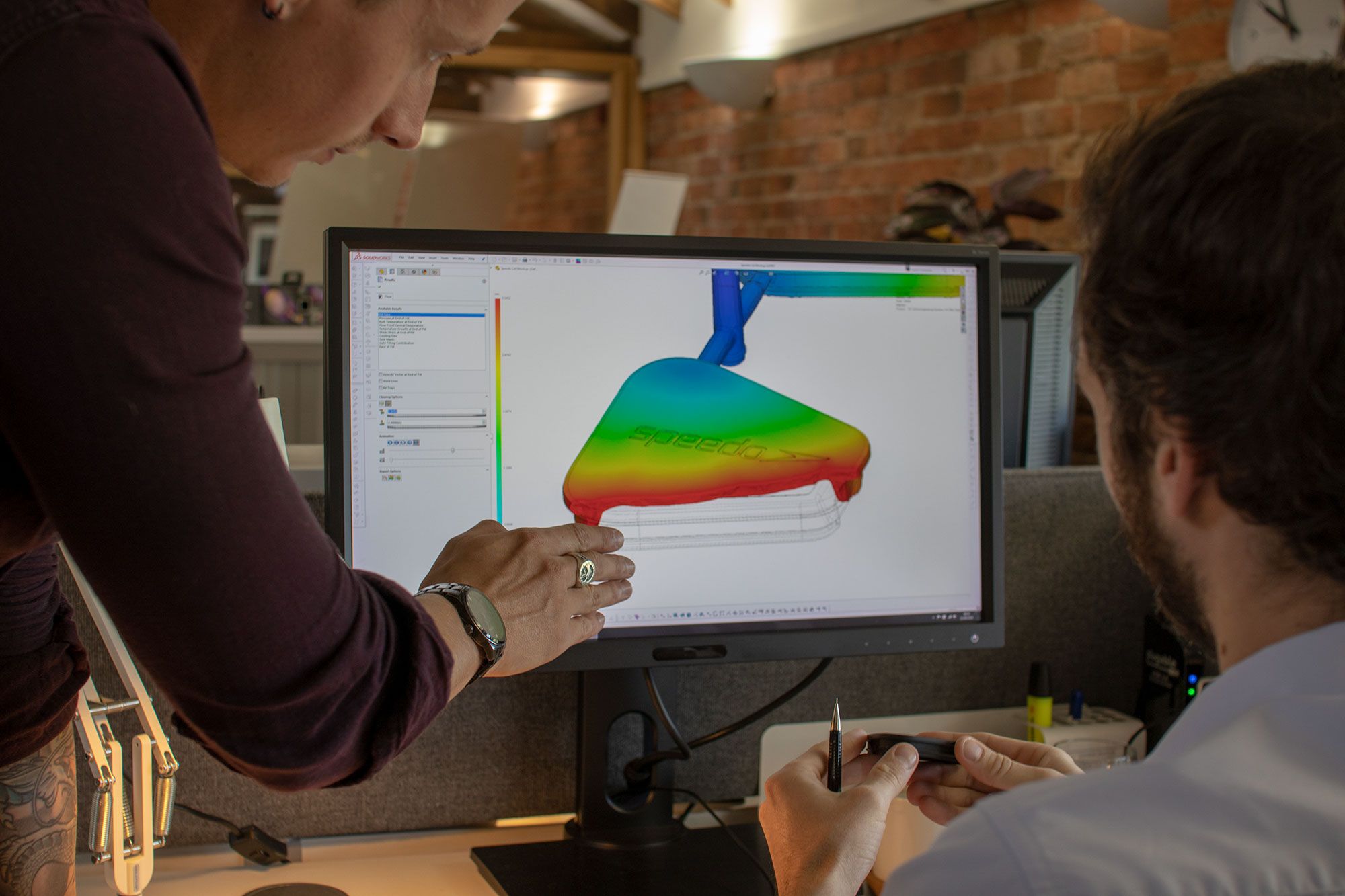

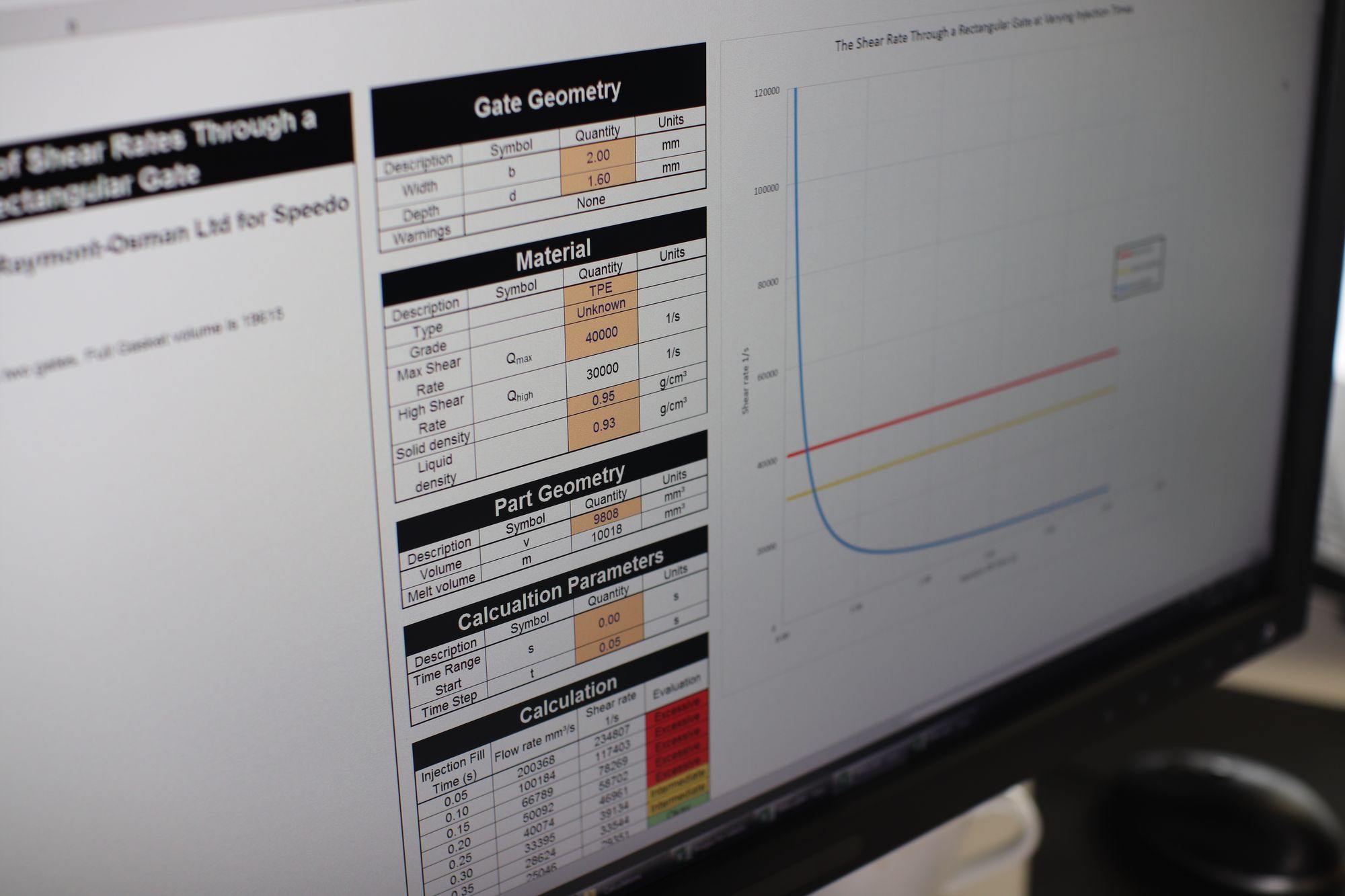

Design development is our speciality at Raymont-Osman Product Design. Developing a design requires practise, experience, expertise and a good knowledge of how parts can be manufactured and assembled.

Choosing the colour, materials and finish (CMF), precisely mechanically engineering mechanisms and working with suppliers to define mouldings can dramatically impact the cost and quality of the end product.

Injection mould gates, split lines and assembly features are the small details that define the quality of the product, and they can make a significant difference in how a product works and feels. Good design development can also dramatically impact the number of returned products, and in some cases, this alone can pay for the project.

Design Development makes the difference between a five star rating and a one star fail when it comes to the end product. There are several steps when defining development depending on the project and the main ones are:

- Specification

- CAD Design

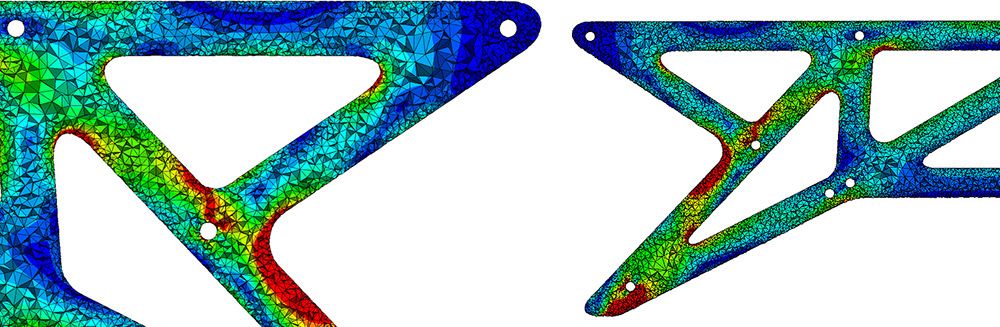

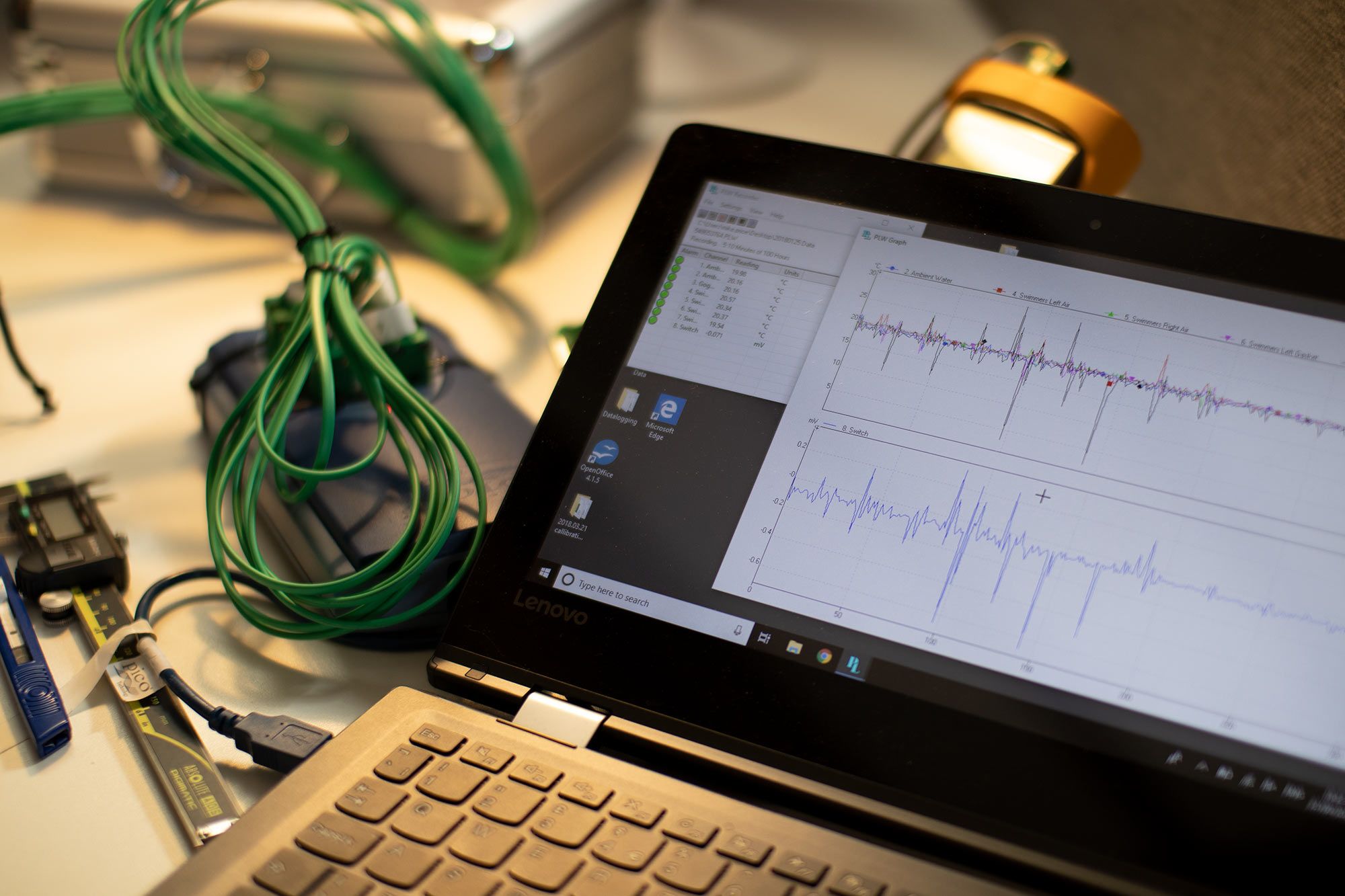

- Simulation and Testing

- Failure Mode & Effects Analysis (FMEA, dFEMA and pFMEA)

- Working with suppliers

4. Production

Before going into production a supplier will require a Techpack (or Technical Drawings depending on your industry). These dimensioned drawings act as a specification between design and manufacturing to make sure that parts are made correctly.

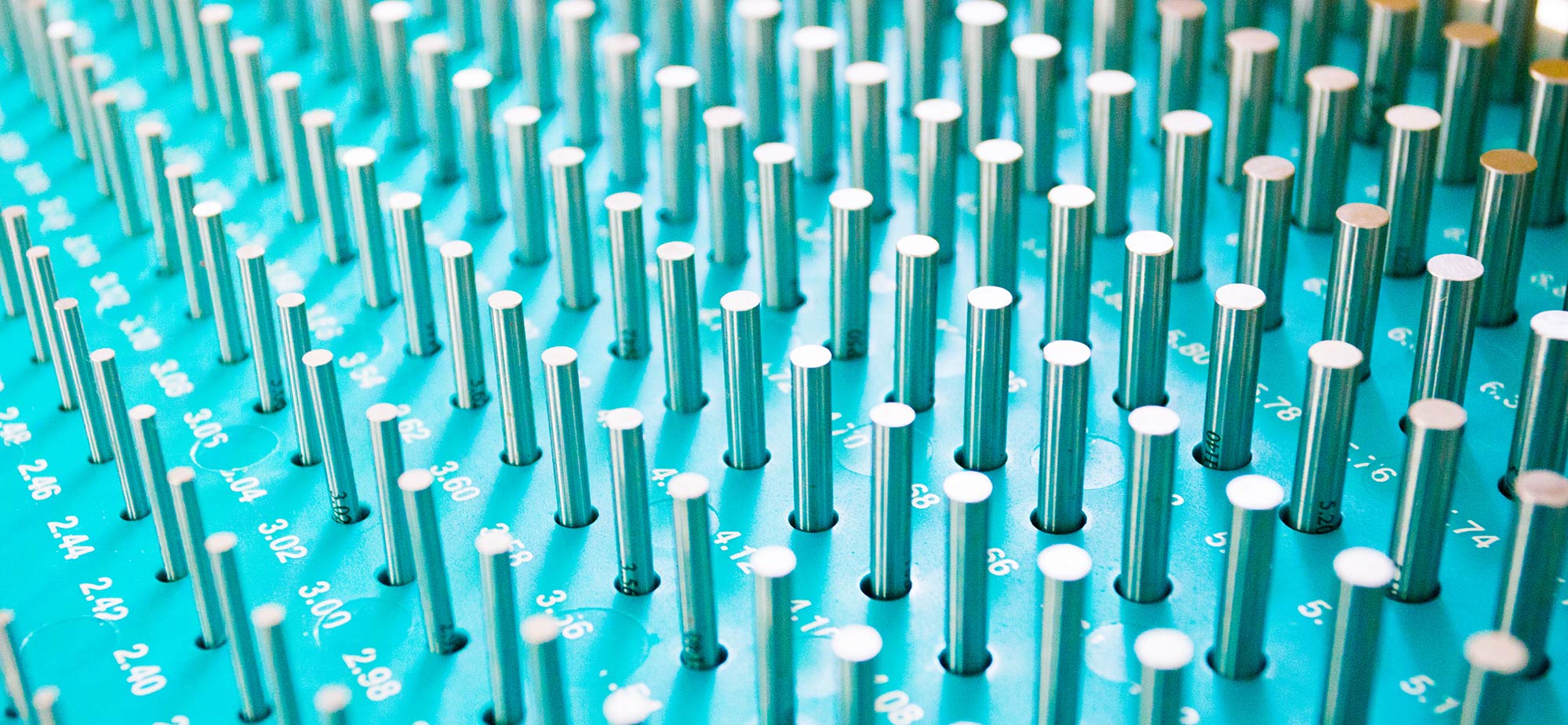

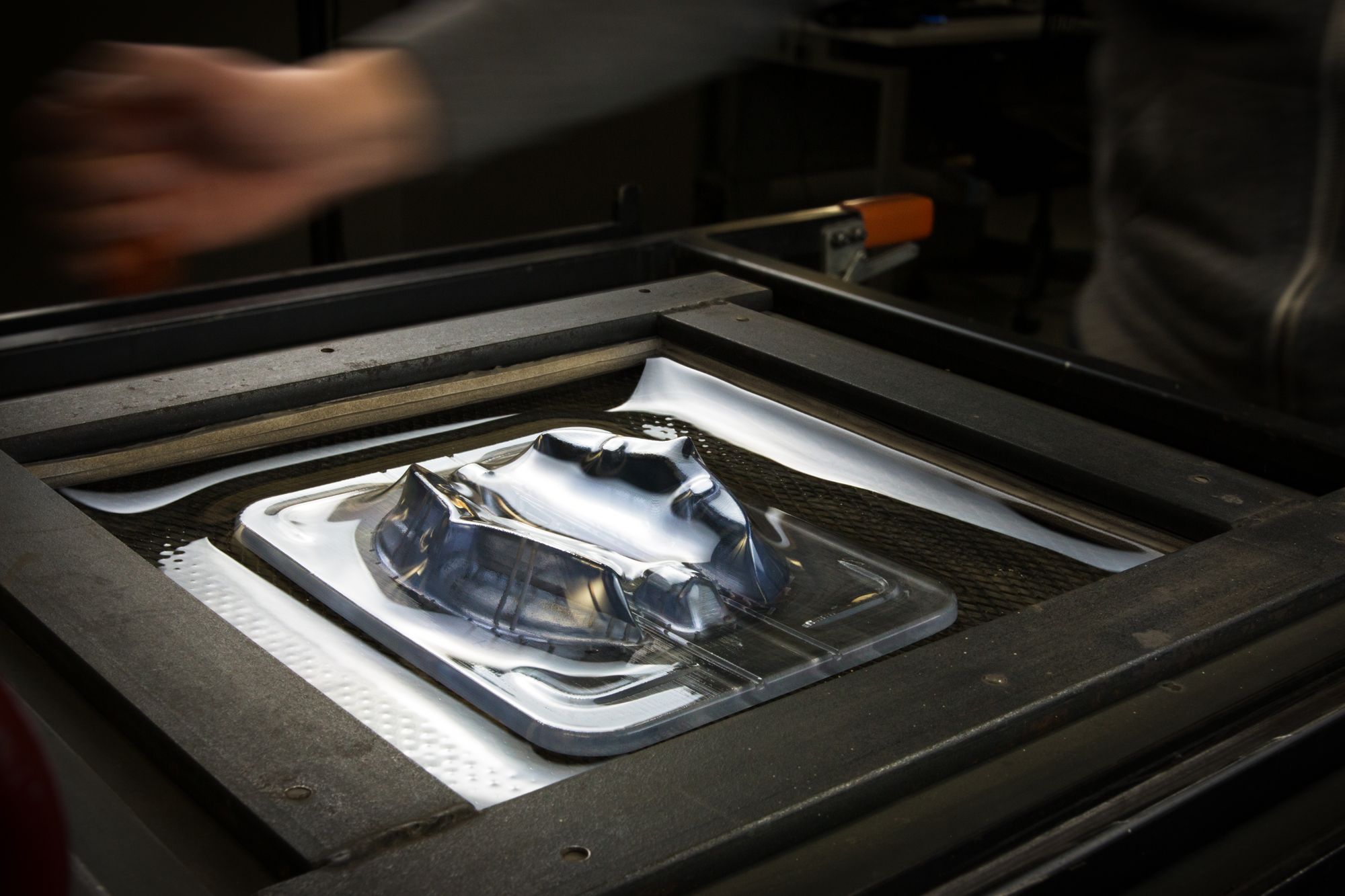

When plastic parts need to be made, a mould tool is used to form the product. The mould tool can vary significantly in cost and complexity and it’s quite common to go through a few versions of the tool (the industry jargon is T1, T2 tools) before things are ironed out. Different versions of a mould tool are necessary to iron out moulding defects and plastic flow problems that can cause dimensional variation.

Samples

It’s not uncommon for these early mouldings (or any samples actually) to get snapped up - taken to photoshoots and sales pitches. In fact, these samples are often specifically called Salesman Samples. But from a design and engineering standpoint, it's important to try and retain these samples for testing and quality later on because they can be very useful if quality starts to slip in production.

5. Evaluation

The point of production is where the Design and Engineering teams often breathe a heavy sigh of relief and hand over to sales, distribution and marketing, however, it’s always important to evaluate a project and gather feedback for future designs.

Sales Data and customer feedback (including Amazon reviews) can help improve future products and can be the foundation for the next product research. You should strive for continual product development, evolving a product to keep up with market trends and ironing out issues.

Conclusion

These 5 steps: Product Research, Concept Design, Design Development, Production and Evaluation are the cornerstone of modern product design.

Finally, it's important to note that, in the real world, things are rarely this simple. Sometimes stages get missed, sometimes ideas don’t work, sometimes budgets run low. If this happens then be aware that cutting corners in development (for example) can lead to larger and costlier problems in manufacturing.

However; when done correctly, designing a product can be a lucrative and fantastic experience. As with many things, experience helps a great deal and if you would like help with designing a product, then please get in contact.